We know manufacturers across industries have been striving for years to create the ideal balance between operational efficiency and product quality. To achieve this balance, Manufacturing Operations Management (MOM) is considered an innovative approach that can help optimize the production process. But what is MOM, and how it really can help manufacturers? Let’s dig deep without wasting any time to help with everything you need to know about manufacturing operations management.

Understanding What is Manufacturing Operations Management (MOM)

Simply put, Manufacturing Operations Management (MOM) is a comprehensive suite of software solutions and strategies specifically designed to help optimize and streamline the entire manufacturing process. This means that MOM (a perfectly apt acronym) can handle everything, from initial planning and scheduling stages to execution and quality control.

Integrating other systems and retrieving data from them also helps MOM to provide manufacturers with real-time visibility and control over their operations, ensuring enhanced efficiency, reduced costs, and better product quality.

Core Components of MOM

A typical MOM system includes numerous key components, each playing a critical role in the overall manufacturing process:

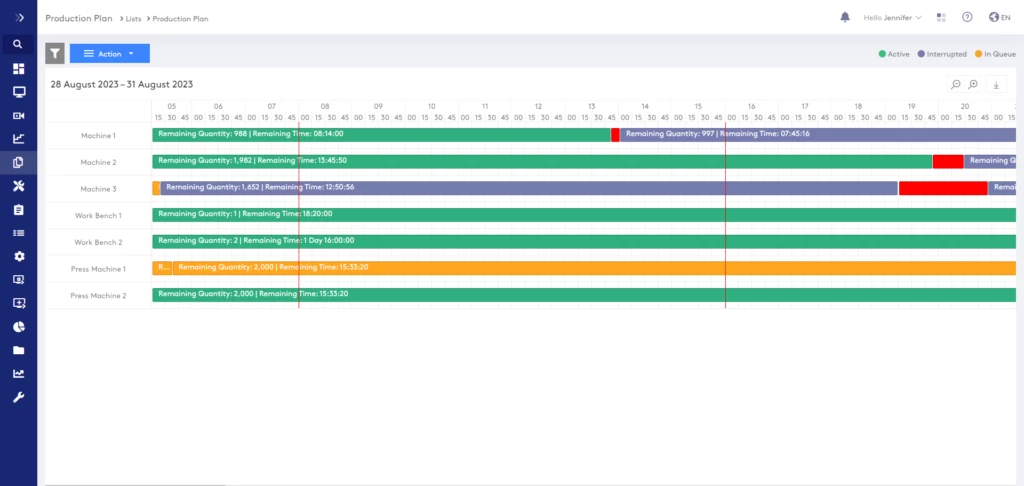

- Production Planning and Scheduling: This is considered an extremely vital component. It optimizes resource allocation, balances workloads, and creates detailed production schedules, ensuring the manufacturing operation is fully efficient and resources are used effectively.

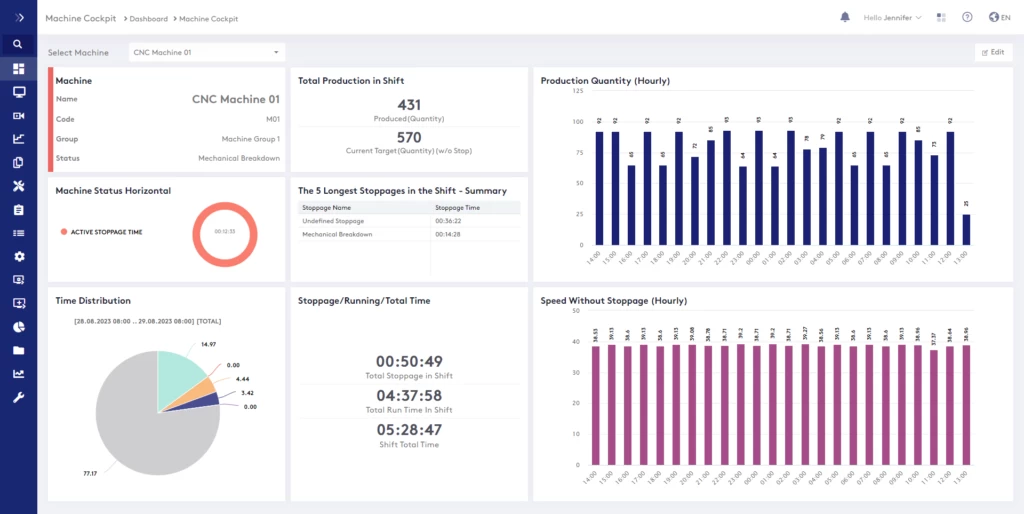

- Manufacturing Execution (MES): The MES component helps manage real-time shop floor operations and performs operations like labor management, work order execution, and equipment monitoring to ensure all manufacturing processes run smoothly and efficiently.

- Quality Management: Another extremely important component is Quality Management, which works within MOM to ensure product quality through rigorous inspection, testing, and corrective actions. And that’s not it. The quality management component also helps to maintain high standards and reduce the risk of defects.

- Maintenance Management: Planning and executing preventive and corrective maintenance to maximize equipment uptime are parts of Maintenance Management. This component also ensures that machinery is well-maintained and operational, minimizing downtime and extending the lifespan of equipment.

- Supply Chain Management: This component acts as a coordinator. It ensures that the flow of materials, inventory management, and supplier relationships are fully aligned and that the materials are available whenever needed.

- Manufacturing Intelligence: Last but not least, this component collects and analyzes data to help identify trends, optimize processes, and improve decision-making. In other words, it gives you all the important insights required to fine-tune operations and drive continuous improvement.

The Many Benefits of Implementing MOM

We have seen many manufacturers enjoy numerous benefits of MOM through on-time implementation, including:

- Increased Efficiency: There’s no denying that MOM streamlines operations, reduces downtime, and optimizes resource utilization, which ultimately leads to significant improvements in efficiency.

- Vastly Improved Quality: There’s no point in increasing production if the quality level drops. MOM can help enhance product quality through robust quality control processes and real-time monitoring, reducing the likelihood of defects and ensuring customer satisfaction.

- Enhanced Visibility: Did you know that MOM provides real-time insights into production performance and supply chain status? This does a phenomenal job of better monitoring and control.

- Faster Time-to-Market: We know very well how efficient planning and execution accelerate product development and launch. This can give manufacturers a competitive edge over others. MOM can do that big time.

- Reduced Costs: And how can we forget about cost savings? Optimized resource allocation, minimized waste, and improved overall cost-effectiveness, resulting in substantial cost savings.

- Compliance Adherence: MOM also does a great job of ensuring compliance with industry regulations and standards. This helps reduce the risk of non-compliance and associated penalties.

- Improved Decision: And that’s not all. Making data-driven insights supports informed business decisions and helps manufacturers navigate challenges and seize opportunities.

A Cloud-Based MES Approach, ProManage Cloud

ProManage Cloud is an MES approach that combines the benefits of a traditional manufacturing execution system with modern workflow management technology. It is a cloud-based system, so operational processes such as KPIs and reporting can be captured for reuse and sustainable standardization across multi-tasking needs.

This approach provides the following benefits:

Rapid Implementation and Deployment: Cloud-based structure enables rapid definition and implementation of new processes and changes.

Multi-Tasking Compatibility: Operational processes, KPIs, and reporting can be reused and standardized across the entire facility.

Continuous Improvement: Operational data enables constant monitoring and improvement of processes and performance.

Enterprise Flexibility: Cloud-based structure enables rapid adaptation to changing business requirements.

Increased Efficiency: Cost savings are achieved through improved operational efficiency, quality improvements, and regulatory compliance.

The Bottom Line

We know how powerful of a tool MOM can be when it comes to helping manufacturers achieve operational excellence and gain a competitive edge. That being said, it is high time manufacturers invest in a robust MOM solution and leverage the latest technologies to unlock new opportunities for growth and success. As the manufacturing landscape evolves, MOM will play an increasingly vital role in driving efficiency, quality, and innovation. Don’t fall behind for embracing MOM late.

Would you like to delve deeper into a specific aspect of MOM, such as its implementation challenges, or explore how it is used in particular industries? Contact us to learn more.

[formsite host=”fs26″ key=”m_OmK8apOTD1rsQA7j37rujXAIk-siNwK5oMHUOxJy8″ width=”100%”]