In the manufacturing industry, traditional Manufacturing Execution Systems (MES) are no longer sufficient to meet the demands of the constantly evolving landscape. Manufacturers face challenges, such as limited budgets, time constraints, and uncertainties in their path to digital transformation. This has given rise to the emergence of next-generation MES solutions that offer easy integration, user-friendly interfaces, and real-time visibility into processes.

In this blog post, we will explore the evolution of MES solutions, their impact and advantages in the manufacturing industry, and how ProManage Cloud, a leading next-gen MES solution, can help manufacturers seize the opportunities presented by this new era of MES.

The Evolution of MES Solutions

To fully understand the value and impact of next-generation MES solutions, it is important to recognize the limitations of traditional MES systems. Traditional MES systems have been the backbone of manufacturing operations for years but often face challenges related to inflexibility, complex implementation, and outdated interfaces.

These legacy systems were designed to track and trace operational activities across factories and processes but were not built with the agility and scalability required in today’s fast-paced manufacturing environment.

The Impact of Next-Gen MES on the Manufacturing Industry

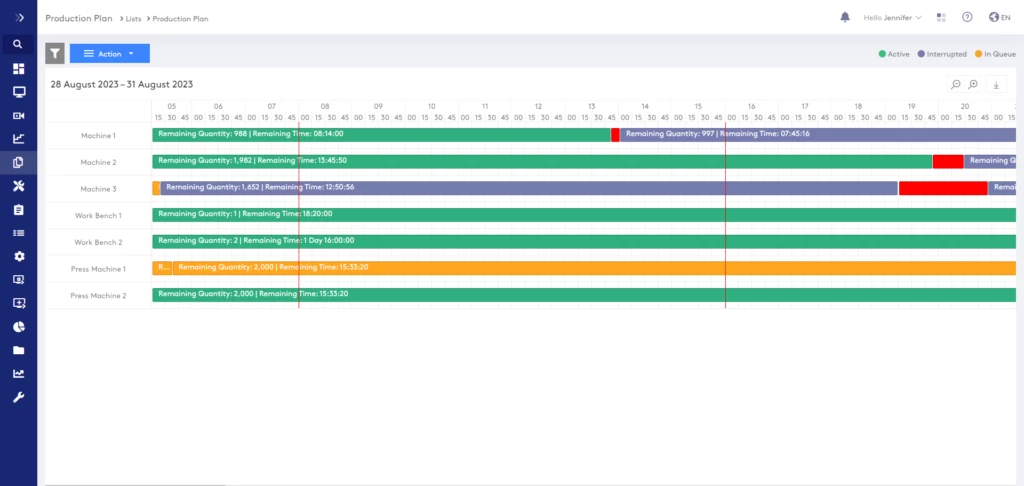

Next-generation MES solutions are revolutionizing the manufacturing industry by improving productivity, enhancing quality control, and enabling real-time decision-making. Manufacturers who adopt next-gen MES systems can gain a competitive edge by streamlining their operations, reducing costs, improving customer satisfaction, and responding quickly to market demands.

These solutions provide manufacturers with advanced capabilities such as predictive analytics, machine learning, and IoT integration, allowing them to optimize production processes, proactively identify bottlenecks, and enhance overall efficiency.

Advantages of Next-Gen MES

Next-generation MES solutions address common pain points faced by manufacturers, offering critical advantages that drive agile, scalable, and human-centric smart manufacturing. Here are some key advantages of next-generation MES solutions:

Scalability & Flexibility: Next-gen MES systems enable incremental implementation, allowing businesses to start small and gradually expand into a comprehensive MES solution as their operations grow. This flexibility ensures that manufacturers can adapt to changing business needs without major disruptions.

Ease of Use: Next-gen MES solutions prioritize operator involvement by offering a no-code platform and an easy-to-use interface. These intuitive interfaces empower frontline workers to quickly adapt to new technologies and actively participate in optimizing processes. Additionally, ready-made reports and training materials simplify the onboarding process, reducing training time and costs.

Integration: Next-gen MES solutions facilitate seamless integration into existing business intelligence (BI) tools and enterprise resource planning (ERP) systems, enhancing connectivity and data exchange. By integrating MES with other systems, manufacturers can leverage data from various sources, gain comprehensive insights, and make informed decisions.

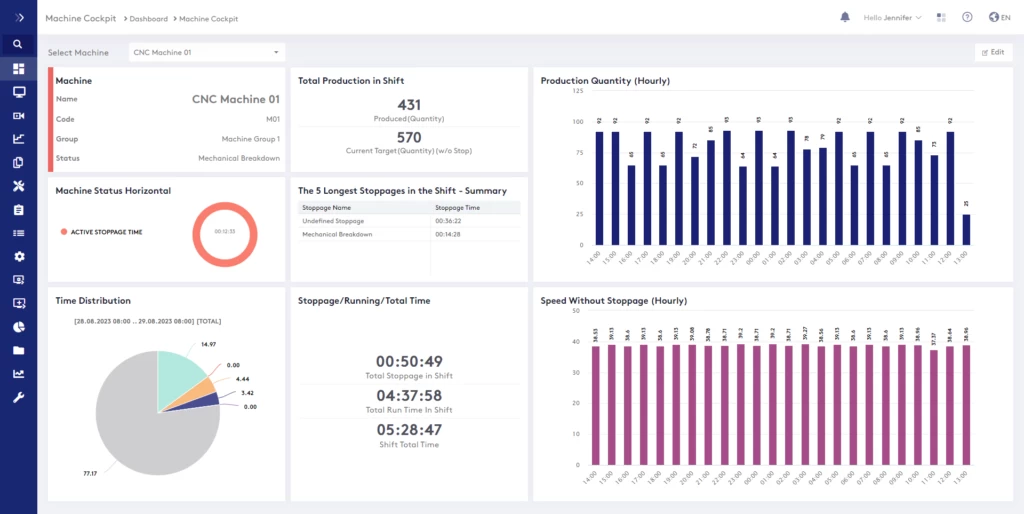

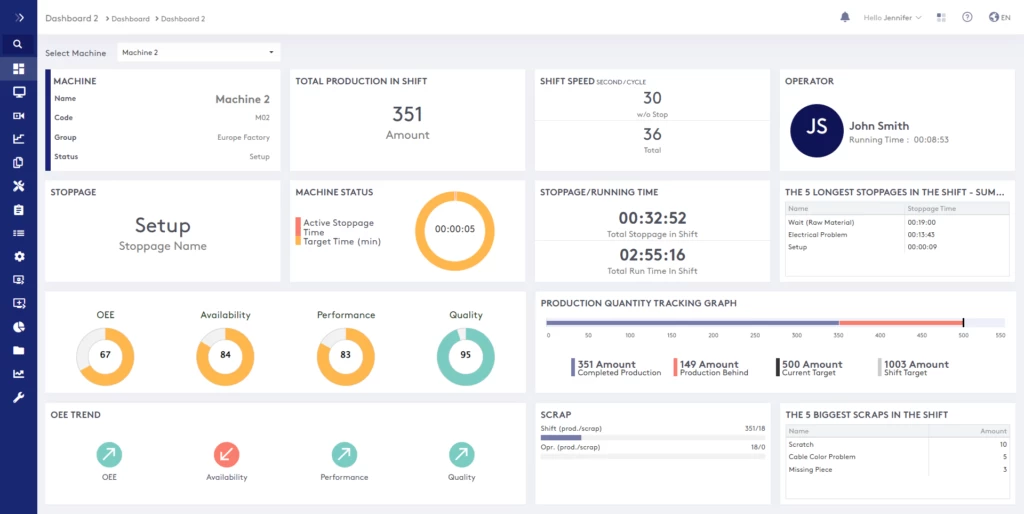

Real-Time Data Accessibility: Next-gen MES solutions provide manufacturers with real-time data, enabling proactive issue resolution and data-driven decision-making. With instant access to accurate, up-to-date information, supervisors and operators can identify and resolve issues promptly, minimize downtime, and optimize production processes.

To fully capitalize on the opportunities provided by next-gen MES solutions, manufacturers must ensure a smooth transition to implementing comprehensive MES. Here are some steps manufacturers can take to successfully implement next-gen MES:

Assess Current Capabilities and Pain Points: Evaluate current systems, processes, and pain points to identify areas that need improvement and determine the specific requirements for the next-gen MES solution.

Define Objectives and Prioritize Use Cases: Clearly define the objectives of implementing next-gen MES and prioritize use cases based on their potential impact on operational efficiency, cost reduction, and customer satisfaction.

Choose the Right Next-Gen MES Solution: Thoroughly evaluate and select a next-gen MES solution that aligns with the identified objectives and addresses the specific pain points of the manufacturing operations, including ease of use, data accessibility, and effortless implementation.

Involve Supervisors & Operators: Involve supervisors and operators in the implementation process, ensuring their buy-in and providing comprehensive training to ensure they are proficient in utilizing the new system effectively.

Monitor and Optimize: Continuously monitor the performance of the next-gen MES system, gather feedback from users, and make necessary adjustments to optimize its use and extract maximum value.

ProManage Cloud: IoT-Based, Next-Generation MES Solution

When searching for the right MES solution, look no further than ProManage Cloud. ProManage Cloud is an IoT-based, next-generation MES solution that offers a step-by-step approach in which manufacturers can easily step into digital transformation that leads to a comprehensive solution. Supervisors can address issues promptly using real-time data from their mobile devices.

With its one-day deployment, ProManage Cloud ensures an effortless implementation process. Additionally, its data buffering capabilities prevent data loss, and compatibility with smart manufacturing technology makes integration seamless. ProManage Cloud empowers manufacturers with a focus on continuous improvement and a comprehensive set of tools and features to track, optimize, and improve manufacturing operations.

Stay Ahead With ProManage Cloud

Next-generation MES solutions, such as ProManage Cloud, are transforming the manufacturing industry by enabling agile, scalable, and human-centric smart manufacturing. These solutions offer numerous advantages, including scalability, ease of use, seamless integration, and real-time data accessibility.

By adopting next-gen MES solutions, manufacturers can streamline their operations, improve productivity, enhance quality control, and respond quickly to market demands. With the right strategy and implementation approach, manufacturers can stay ahead in the era of digital transformation and drive success in the dynamic manufacturing landscape.

Reach out to us to learn more about ProManage Cloud and its next-generation MES capabilities.