The manufacturing industry faces its most substantial change since the Industrial Revolution at present. The combination of interconnected systems with artificial intelligence and real-time data analytics in smart factories transforms manufacturing operations to achieve enhanced efficiency and quality and faster responsiveness. The Manufacturing Execution System (MES) functions as the essential link between enterprise planning and shop floor operations which enables smart manufacturing to become a reality.

From Traditional Production to Connected Manufacturing

The manufacturing industry maintained its operations through separate systems and manual procedures for many years. The different systems operated independently for production planning and quality tracking and machine performance monitoring. The fragmented operational structure produced isolated information systems which blocked visibility while slowing down decision processes and restricted complete operational optimization.

The smart factory revolution establishes a completely interconnected manufacturing system which transforms traditional operational methods. The environment connects all machines and processes and operators through a complete network which allows real-time data exchange and immediate feedback and coordinated responses to changing conditions. The MES functions as the central control system of this connected environment by managing information flow to achieve synchronized component operation.

The factory floor connectivity reaches beyond production areas to include all components of the value chain. Suppliers and logistics partners and customers join an integrated network that enables seamless information flow to achieve exceptional collaboration and coordination levels. The manufacturing operation achieves both enhanced efficiency and fundamental intelligence and responsiveness through this system.

MES for Quality Control and Traceability Reducing Defects in Manufacturing

Real-Time Visibility: The Foundation of Smart Operations

The major advancement of smart factories exists in their transition from periodic reports to continuous real-time monitoring. Traditional factory operations based their performance understanding on reports which were either produced at the end of shifts or as daily summaries. Major time and resources went to waste before problems were discovered.

The present generation of MES solutions gives instant access to every detail of production operations. The current production rates together with quality metrics and equipment status and resource utilization become accessible in real-time for managers. The immediate availability of data allows proactive decision-making rather than delayed problem-solving. Maintenance operations can be planned ahead of time when a machine displays signs of degradation to prevent equipment failure. The system enables quality parameters to be adjusted through immediate feedback before producing defective products.

This real-time visibility also enables dynamic optimization. Production scheduling becomes possible through real-time modifications based on operational conditions at present. The system adjusts resource distribution according to shifting operational needs. Real-time feedback allows businesses to adjust their quality parameters during production operations. The manufacturing process transforms into an adaptive operation which improves continuously instead of following predetermined plans.

Integration: Breaking Down Operational Silos

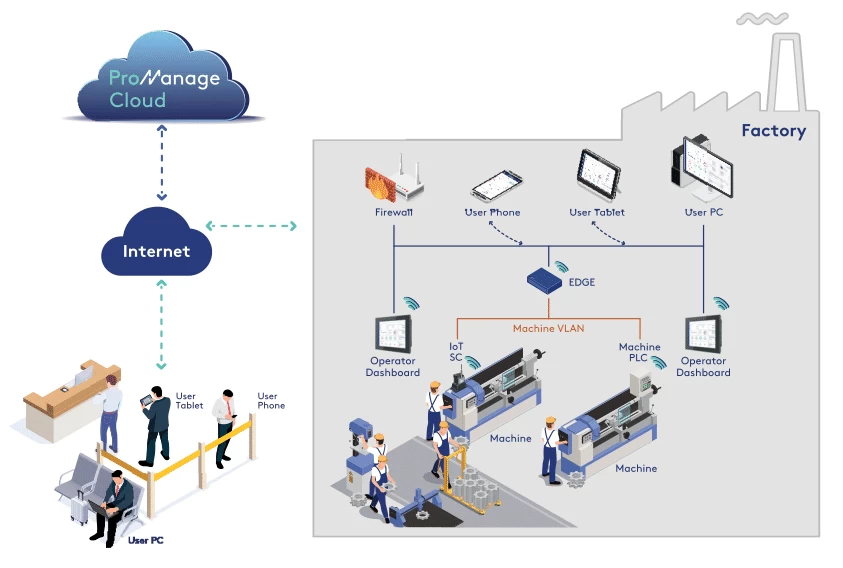

The transformation of smart factories demands that separate operational systems and processes must integrate into a unified system. The MES functions as a crucial integration center which connects enterprise resource planning (ERP) systems with quality management systems and maintenance management systems and shop floor automation.

The integrated system provides operational oversight that supports better decisions across all organizational levels. Financial planning becomes possible through production data that updates in real-time. The analysis of complete production parameters enables organizations to develop quality improvement initiatives. Maintenance schedules should use actual equipment performance instead of fixed time intervals for optimization purposes.

The integrated system allows organizations to achieve advanced levels of product tracing as well as compliance management. The system tracks every product from raw materials to finished goods while displaying complete details about all production steps and quality checks and handling procedures. The complete traceability system supports regulatory requirements while allowing swift responses to quality issues and continuous improvement programs.

Flexibility and Scalability for Future Growth

The current manufacturing operations need to adapt fast to market changes and new product launches and shifting customer demand patterns. Advanced MES solutions orchestrate smart factories to deliver the necessary adaptability for success in dynamic market environments.

The production lines can be quickly adjusted to start producing new products. The quality control parameters can be modified according to various product requirements. The system can distribute resources in an optimal manner based on changing customer needs. The technology demonstrates flexibility through cloud-based solutions that enable organizations to scale their operations for growth and expansion.

Modern MES solutions have a modular design which enables organizations to perform their transformation at their own pace. Organizations can begin implementing smart factory capabilities through essential areas before expanding their implementation across different parts of the organization. The step-by-step approach decreases risks and prevents disruptions while enabling organizations to learn and adapt during their transformation journey.

Embracing the Smart Factory Future

The transition to smart manufacturing requires more than technology implementation because it demands complete rethinking of manufacturing operations optimization and integration and continuous improvement methods. The MES functions as the base for this transformation because it enables full smart factory operational potential through connectivity and visibility and intelligence.

Organizations that transform their operations gain substantial competitive benefits through enhanced efficiency and quality and faster responses and greater adaptability. Organizations which postpone their smart factory transformation risk losing ground to competitors who have initiated their smart factory development.

ProManage delivers complete MES solutions which enable successful smart factory transformations by providing essential integration features and real-time monitoring capabilities and advanced analytical tools for manufacturing operation transformation. ProManage guides manufacturers through complex smart factory implementation while delivering measurable business outcomes because of their digital transformation expertise and ongoing innovation commitment.

Our team at ProManage stands ready to help your organization transform into a smart factory through our solutions which will drive future success.