There’s no denying the significant role Manufacturing Execution Systems (MES) play in revolutionizing the manufacturing industry. Organizations across the globe are increasingly gravitating towards MES when they find themselves at pivotal moments of change, such as upgrading their ERP systems, striving for higher quality, reducing waste, slashing costs, or seeking to enhance asset utilization without the hefty price tag of new production lines. The push for an MES is also strong when current systems fall short of meeting the evolving needs of a dynamic business environment.

It makes sense since opting for MES software brings a plethora of transformative benefits to the forefront of manufacturing operations:

📌Deeper analysis and understanding of the manufacturing processes

📌Availability of real-time operational data

📌Superior traceability and adherence to compliance standards

📌Significant improvements in quality management

📌Optimized maintenance operations

📌Prompt execution of manufacturing orders

📌Streamlining operations through paperless workflows

📌Reduction of errors attributable to manual processes

📌Minimized production waste, enhancing sustainability

📌Precision in inventory management

However, the true challenge lies in identifying and selecting the RIGHT MES that perfectly matches the unique requirements of your organization.

The following guide aims to illuminate the essential factors to consider when navigating the complex landscape of MES software, ensuring that your choice not only adds value but also serves as a catalyst for growth and innovation.

Factors To Consider When Choosing The Right MES Software

These are the most important factors each company should consider before investing in a new MES system:

#1: Understand What Are Your Requirements Are

Start your selection process by conducting an in-depth analysis of your company’s manufacturing operations, identifying key areas for enhancement such as product quality, inventory accuracy, traceability, and efficient production planning. It’s crucial to engage a diverse group of stakeholders within the company to ensure that a well-rounded set of requirements is collected.

This comprehensive approach not only aids in pinpointing the exact functionalities your MES software should offer but also ensures the chosen solution drives significant improvements in operational efficiency and output quality. Additionally, this step emphasizes the importance of aligning the MES with your strategic goals, thereby ensuring a robust foundation for future scalability and adaptability in your manufacturing processes.

#2: MES System’s Core Functionality Should Meet Your Requirements

Key elements of a Manufacturing Execution System (MES) include:

✅Data handling and management

✅Allocation and management of roles

✅Management of tools and resources

✅Oversight of production orders

✅Provision of real-time, precise manufacturing data

✅Consolidation of all shop floor information into a unified database

✅Efficient and accurate communication among all parties involved

✅Storage and documentation of production details for creating a detailed, accurate historical record

✅Immediate evaluation of ongoing production statuses

✅Implementation of quality assurance measures

✅Interface for machine operations

✅Management of items and materials

Additionally, it’s crucial that the chosen MES system integrate seamlessly with other existing systems to ensure a smooth and efficient workflow across the organization.

#3: It Should Offer Scalability and Adaptability

Opt for an MES software that offers scalability and adaptability, essential for growing alongside your business and accommodating evolving operational needs. A system with high flexibility enables tailored customizations and seamless integration with pre-existing applications and systems, ensuring smooth transitions and continuity in operations. This adaptability is crucial not only for meeting current demands but also for future-proofing your manufacturing processes, allowing for expansions or modifications without significant overhauls.

Additionally, a scalable MES solution supports incremental growth, ensuring that as your business expands, your software capabilities can adjust accordingly, avoiding the pitfalls of system obsolescence or inadequate functionality. Such a system should also provide a robust framework for integrating new technologies and methodologies, keeping your manufacturing operations at the forefront of efficiency and innovation.

#4: Consider The Overall Cost Factor

When considering the adoption of a Manufacturing Execution System (MES), it’s crucial to thoroughly evaluate the financial implications, including both the initial outlay and the ongoing operational expenses. This evaluation should encompass not just the upfront purchase price but also encompass installation charges, licensing fees, consultancy services, training programs, and regular maintenance expenses.

Often overlooked are the ancillary costs associated with integrating new automation technologies and updating industrial infrastructure.

These costs are vital for reaching desired operational efficiencies and objectives. A comprehensive budgeting process, therefore, must begin with a detailed analysis of the additional equipment and technologies required, ensuring that all necessary components are accounted for from the outset.

#5: Ensure The System is User-Friendly

Choosing the right Manufacturing Execution System (MES) for your production facility is crucial, not just for its technical capabilities but also for its ease of use. Production environments can be complex and demanding, making it essential for the MES interface to be both ergonomic and intuitive. An accessible interface can significantly reduce the learning curve for operating personnel, enabling them to master the system quickly and efficiently. This swift adaptation is key to ensure that your team can start leveraging the new system to its full potential without delay.

Furthermore, the design of the MES should be thoughtfully crafted, keeping in mind the way employees interact with technology and learn new software. A user-friendly system can positively impact your team’s perception and acceptance of new operational tools, encouraging a smoother transition to new workflows. It’s important to remember that a system that’s easy to navigate not only enhances productivity but also contributes to a more satisfied workforce by reducing frustration and resistance to change.

In addition to selecting a system known for its user-friendly design, involving your employees in the selection process can provide invaluable insights. Gathering feedback on their preferences and experiences with different MES solutions can help you choose a solution that best fits the needs and working styles of your team. By prioritizing user experience and involving your team in the decision-making process, you can ensure the chosen MES will be embraced and effectively utilized, driving improvements in efficiency and productivity across your production operations.

Looking For An Affordable Yet Highly Efficient MES Software?

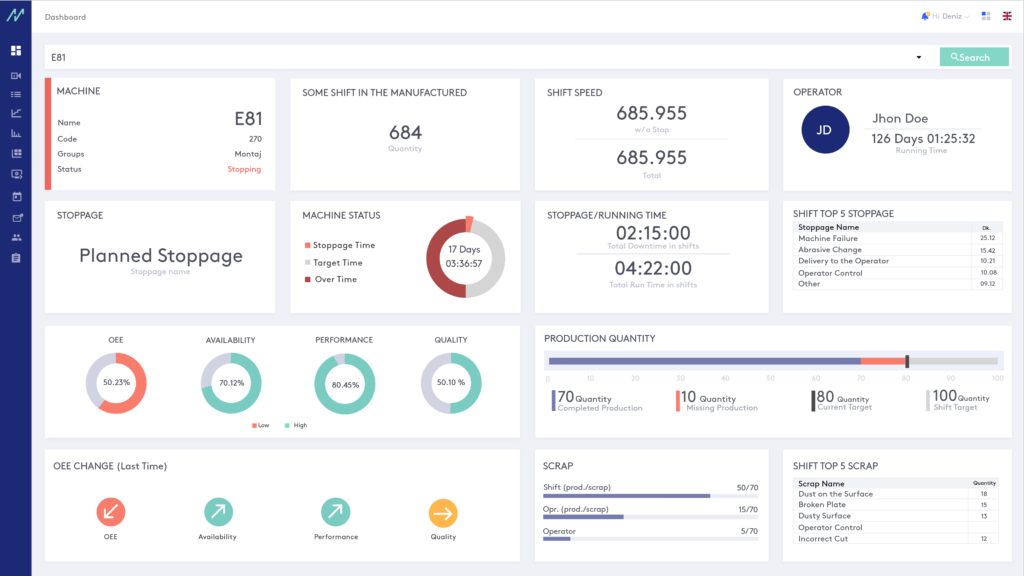

ProManage Cloud introduces a next-generation, IoT-based Manufacturing Execution System designed to revolutionize your production visibility and process management in real-time. This advanced solution ensures a seamless transition and effortless integration with your existing systems, paving the way for enhanced operational efficiency.

Our MES software is tailored to provide comprehensive production management, granting you complete control over your operations. By collaborating with our expert solution consultants, you’ll uncover the specific modules tailored to elevate your manufacturing capabilities to new heights of operational excellence. The best part? All of this comes at a cost that won’t strain your finances.

Contact us to dive into the future of manufacturing with ProManage Cloud’s MES software. Take the first step towards transforming your production processes today.