The complexity and demands of modern manufacturing environments are ever-increasing, driven by globalization, technological advancements, and heightened customer expectations. That being said, these challenges necessitate a robust and adaptable approach to managing production processes, ensuring quality, and maintaining efficiency. Traditional methods often fall short in meeting these demands, leading to the necessity for advanced solutions that can bridge the gap between planning and execution on the shop floor.

Introducing MES

Manufacturing Execution Systems (MES) are sophisticated software solutions designed to monitor, control, and optimize manufacturing operations in real time. MES bridges the gap between the overarching Enterprise Resource Planning (ERP) systems and the actual production floor activities. By capturing data from machines and processes, MES provides valuable insights and control, ensuring that production goals align with strategic objectives. It is the linchpin that ensures seamless integration and synchronization between planning and execution, enhancing overall manufacturing efficiency and productivity.

ProManage’s Expertise

ProManage stands out as a leading MES consultant and provider of Next-Gen MES solutions. With a deep understanding of manufacturing challenges and a commitment to innovation, ProManage offers advanced, cloud-based MES platforms that are modular, no-code, and user-friendly. Their expertise and proven track record make them a trusted partner for manufacturers looking to revolutionize their operations through MES implementation.

But What Does MES Software Do?

MES software encompasses a wide range of functionalities crucial for efficient manufacturing operations:

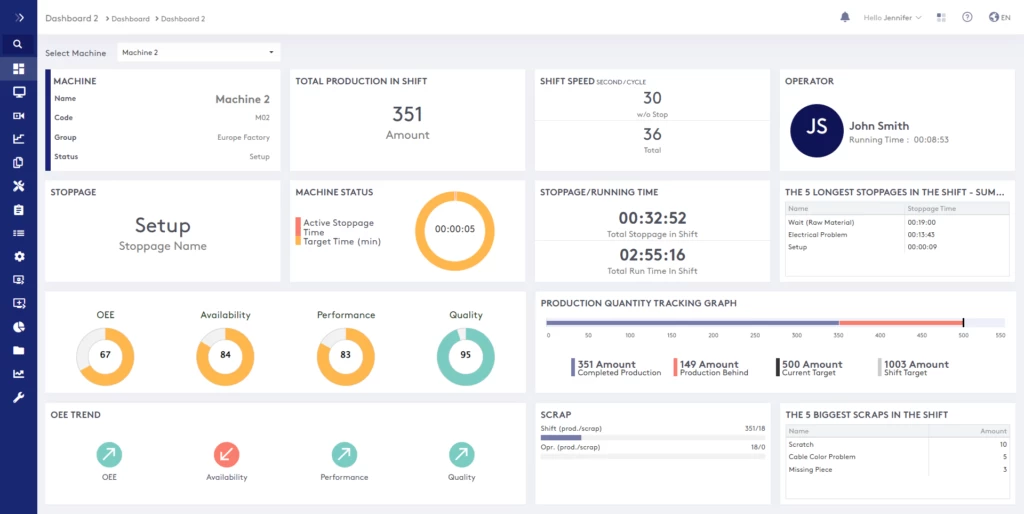

- Data Collection and Analysis from Machines and Processes: MES systems collect real-time data from various machines and processes on the shop floor. This data is analyzed to provide insights into performance, utilization, and potential issues, enabling informed decision-making

- Real-Time Production Visibility and Monitoring: MES offers real-time visibility into production processes, allowing managers to monitor progress, identify bottlenecks, and ensure that production schedules are adhered to.

- Quality Management and Control: MES systems help maintain and improve product quality by monitoring production parameters, ensuring compliance with quality standards, and facilitating proactive issue resolution.

- Inventory and Materials Tracking: By tracking raw materials, work-in-progress, and finished goods, MES ensures that inventory levels are optimized and materials are used efficiently.

- Production Scheduling and Dispatching: MES helps in creating detailed production schedules, dispatching work orders to the appropriate machines or workstations, and adjusting schedules dynamically based on real-time data.

- Performance Analysis and Reporting: MES provides comprehensive reports and analytics on various aspects of production performance, helping in continuous improvement and strategic planning.

Integration with Other Systems

MES software does not operate in isolation. It seamlessly integrates with other critical systems such as ERP (Enterprise Resource Planning), PLM (Product Lifecycle Management), and SCADA (Supervisory Control and Data Acquisition). This integration ensures a holistic approach to manufacturing management, where data flows seamlessly across different systems, enabling a unified view of operations and facilitating better coordination and control.

Key Benefits of MES Implementation

- Improved Efficiency

One of the most significant benefits of MES implementation is the marked improvement in manufacturing efficiency. By reducing downtime, optimizing resource utilization, and streamlining workflows, MES ensures that production processes are as efficient as possible. Real-time data and analytics allow for quick identification and resolution of issues, minimizing disruptions and enhancing overall productivity.

- Enhanced Quality

Quality management is another critical area where MES makes a substantial impact. MES systems reduce defects and ensure compliance with quality standards by closely monitoring production parameters and enabling proactive issue resolution. This leads to higher product quality, increased customer satisfaction, and reduced costs associated with rework and returns.

- Increased Agility

In today’s dynamic market environment, the ability to respond quickly to changes is paramount. MES enhances manufacturing agility by providing real-time visibility into production processes and enabling faster decision-making. This adaptability allows manufacturers to respond swiftly to changes in demand, new product introductions, and other market dynamics.

- Cost Reduction

MES helps in significantly reducing manufacturing costs. By optimizing inventory levels, minimizing waste, and increasing throughput, MES reduces the overall cost of production. Efficient resource utilization and reduced downtime further contribute to cost savings, making MES a valuable investment for any manufacturing operation.

- Data-Driven Insights

The data collected and analyzed by MES provides actionable insights that are crucial for continuous improvement. By leveraging these insights, manufacturers can identify areas for improvement, implement best practices, and drive ongoing enhancements in productivity, quality, and efficiency.

Why Choose ProManage as Your MES Consultant?

ProManage offers a cutting-edge, cloud-based MES platform that brings modern technology to manufacturing operations. This next-gen MES solution is designed to be flexible, scalable, and highly efficient, catering to the diverse needs of manufacturers across various industries.

Also, ProManage’s MES platform features a no-code, modular approach, making it easy to implement and customize. This approach reduces the time and cost associated with deployment and allows manufacturers to tailor the system to their specific requirements without extensive technical expertise.

Moreover, we have a proven track record of successful MES implementations across different sectors. Their expertise is backed by numerous client case studies and testimonials that highlight the tangible benefits and improvements achieved through their solutions.

ProManage offers comprehensive consulting services, guiding clients through every step of the MES implementation process. From initial needs assessment and system design to deployment, training, and ongoing support, ProManage ensures that manufacturers get the maximum value from their MES investment.

Contact Us Today

If you’re looking to transform your manufacturing operations into agile, efficient, and responsive ecosystems, contact ProManage for a free consultation. Our experts are ready to discuss your MES needs and help you find the perfect solution tailored to your business requirements.

ProManage can revolutionize your manufacturing operations with its next-gen MES solutions, turning challenges into opportunities and ensuring your business remains competitive in today’s dynamic market. With ProManage, experience the future of manufacturing today.