The key for manufacturers looking to transform their production processes lies in applying agile manufacturing principles. A crucial step is integrating Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES). But why is this integration so important Because MES and ERP integration enables seamless communication between the shop floor and the top floor, ensuring that production plans are aligned with business objectives. This integration provides real-time visibility into manufacturing operations, allowing for more informed decision-making, improved efficiency, and better resource utilization.

Here, we will delve into the intricacies of MES-ERP integration and explore how it can be a game-changer for manufacturers seeking to optimize their production processes.

Reasons Why MES and ERP Integration is Important?

The advantages of MES and ERP integration are numerous, such as:

Seamless Data Integration

Integrating of ERP and MES facilitates unified data sharing in real-time, enabling synchronized operations. By bringing together these two systems, manufacturers can align various business processes, ensuring uninterrupted data flow from the order stage all the way to the production line.

By bridging the gap between ERP and MES, manufacturers gain access to real-time insights into their production processes. This continuous stream of data equips them with the ability to make informed decisions promptly. Furthermore, this integration enhances operational transparency, allowing for better coordination between different departments. As a result, manufacturers can optimize production schedules, reduce downtime, and improve overall productivity. In essence, the integration of ERP and MES systems can be “vital” for achieving operational excellence in modern manufacturing.

Enhanced Visibility and Control

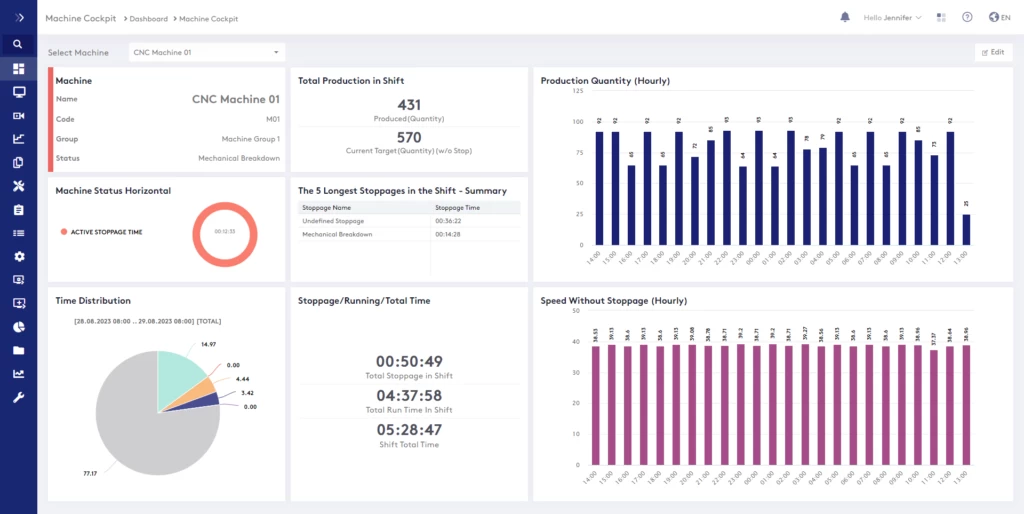

Integrating real-time production data from the shop floor offers an unprecedented level of transparency into the manufacturing process. Managers can monitor progress, identify bottlenecks, and spot potential issues before they escalate. This visibility empowers them to proactively adjust production schedules, ensuring efficient resource allocation and effective management of inventory levels.

Moreover, this optimized control extends to quality assurance, enabling the early detection of deviations from standards and facilitating timely corrective actions. It also supports better communication across departments, fostering a collaborative environment where everyone is aligned with production goals. By providing a holistic view of operations, this approach not only streamlines production but also drives continuous improvement, leading to higher productivity and reduced costs. In essence, real-time visibility and control are fundamental for manufacturers aiming to optimize their production processes and stay competitive in the dynamic market landscape.

Enhanced Demand Forecasting Accuracy

Navigating inventory management in unpredictable times presents challenges. Excess or insufficient inventory can incur significant costs. Delays in delivery or production schedules can jeopardize business integrity. Consistency in demand forecasting is crucial. Integrating ERP with MES enables direct communication of demand changes from the ERP software to production planning.

Also, this integration makes production volumes more adaptable to fluctuating demand, ensuring closer alignment with forecasts. By enhancing demand forecasting accuracy, businesses can effectively streamline inventory management, reduce costs, and uphold a seamless production process. This is essential for staying competitive and profitable in today’s rapidly changing market landscape.

Streamlined Just-in-Time (JIT) Manufacturing

The availability of real-time data through integrated systems revolutionizes the implementation of Just-in-Time (JIT) manufacturing techniques. With precise and timely information, manufacturers can synchronize production schedules with actual demand, significantly reducing waste and minimizing storage costs. This streamlined approach not only enhances operational efficiency but also ensures a faster response to market fluctuations, providing a competitive edge.

Additionally, JIT manufacturing contributes to a leaner production environment, where resources are utilized more effectively, and inventory levels are optimized. By adopting a JIT strategy underpinned by real-time data visibility, companies can achieve a more agile and cost-effective manufacturing process, ultimately leading to improved profitability and customer satisfaction in an ever-changing market landscape.

Minimized Human Error through Automation

The integration of automation and real-time data processing in manufacturing significantly reduces the dependence on manual operations, thereby decreasing the likelihood of human-induced errors. Automated systems ensure that data is collected promptly and accurately from production units and work centers, enhancing the reliability of the information. This accuracy in data input and analysis are essential for establishing credibility in the system and facilitating well-informed decision-making.

By curtailing human intervention, manufacturers can achieve higher levels of precision and consistency in their operations, leading to improved efficiency and productivity. Furthermore, reducing human error contributes to a safer working environment and helps maintain the integrity of the production process, ultimately resulting in higher-quality products and increased customer satisfaction.

Elevated Supply Chain Management

The seamless integration of ERP with MES offers an end-to-end view of the supply chain, from the procurement of raw materials to the delivery of finished products. This holistic perspective enables more effective coordination and management of supply chain activities.

With enhanced visibility across the entire process, manufacturers can achieve more precise demand forecasting, leading to optimized inventory levels and reduced carrying costs. Efficient inventory management ensures that materials are available when needed, minimizing production delays and maximizing throughput. Additionally, timely order fulfillment becomes more achievable, allowing manufacturers to respond quickly to customer demands and market changes.

Why is MES necessary when I have an ERP system?

While ERP systems are crucial for managing various business functions in large manufacturing organizations, they often fail to effectively handle shop floor execution and resource management, including both machinery and personnel. In contrast, manufacturing-focused ERP systems recognize MES as an essential component.

By integrating ERP and MES, your business can leverage the strengths of advancing technology. MES software takes charge of specific tasks like machine scheduling and maintaining traceability through batch management. It bridges the gap between manufacturing operations and the broader organizational framework, ensuring a cohesive and efficient production process.

The Top MES-ERP Integration Source

If you’re seeking a smart integration of ERP with MES, look no further than ProManage. Our ProManage Cloud solution is a game-changer in the industry, designed to increase your production speed and skyrocket your profits significantly!

Reach out to us today, and our ProManage Cloud experts will be happy to address your queries and offer more insights into our platform. Experience a live demonstration and see firsthand how ProManage Cloud can transform your manufacturing operations. Don’t miss this opportunity to elevate your business to new heights!

[formsite host=”fs26″ key=”m_OmK8apOTD1rsQA7j37rujXAIk-siNwK5oMHUOxJy8″ width=”100%”]