In today’s fast-paced manufacturing world, staying ahead means keeping a close eye on all parts of the production process – or else, you’ll be left behind. This has certainly played a huge role in finding integrated technologies to get more efficiency, precision, and real-time oversight. One such innovation for seamless manufacturing processes is called the Manufacturing Execution System (MES). But what is MES and how does it have such a huge impact in transforming traditional manufacturing into more efficient and responsive ecosystem? Let’s find out.

Understanding What is Manufacturing Execution System?

A manufacturing execution system can be better explained as a software-based dynamic solution that is designed to manage, monitor, and execute manufacturing operations in real-time. Think of MES as the ultimate multi-tasker in the factory: it keeps track of all the moving parts, making sure everything runs smoothly, efficiently, and without any hiccups. By collecting data directly from the factory floor, MES helps manufacturers make smarter decisions, improve product quality, and reduce production times. It’s like having a bird’s-eye view of the entire operation, but with the added ability to zoom in on the smallest details whenever needed. According to Global Market Insight, the market value of MES systems will reach 13.5 billion dollars in 2032.

The primary objective of a Manufacturing Execution System (MES) is to optimize the efficiency of manufacturing activities and enhance overall production performance. And to do that, it will monitor and collect accurate, up-to-the-minute information throughout the entire production process.

Industries That Harness The Power of Manufacturing Executing Systems

Manufacturing execution systems have become integral to various industries, streamlining operations and enhancing productivity across the board, such as:

Industrial Manufacturing

Within the realm of industrial manufacturing, MES serves as the backbone for orchestrating intricate production workflows, machinery operations, and material management. It ensures the highest quality standards are met while maximizing efficiency and resource usage. The agility provided by MES allows for rapid adjustments in response to market dynamics or operational challenges, keeping businesses at the forefront of their sectors.

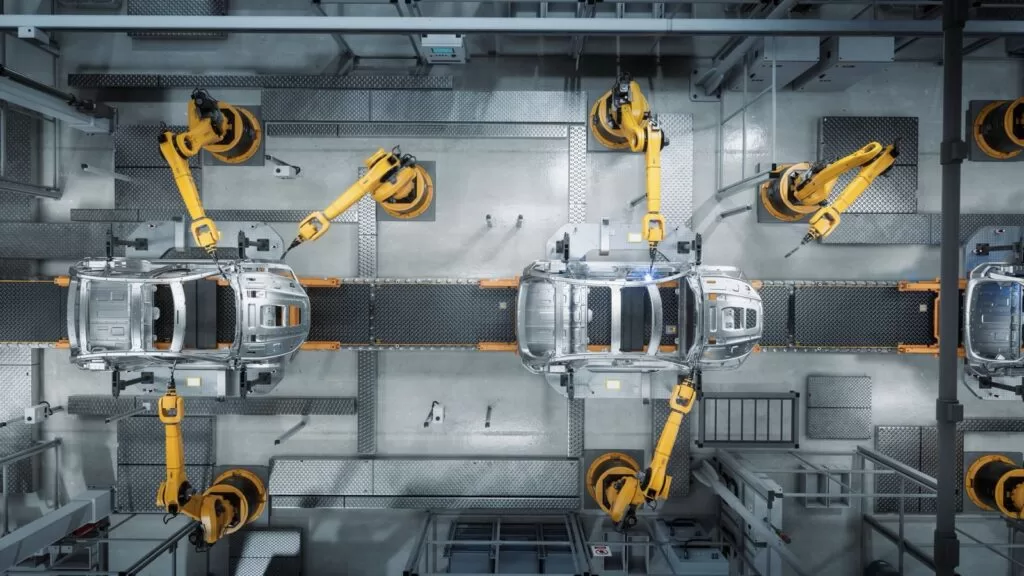

Automotive

One of the roles that Manufacturing Execution System systems fulfill, in the industry is to improve operational efficiency. By bringing together data from sources within the production environment MES enables real time monitoring and analysis of performance metrics. This helps manufacturers pinpoint bottlenecks streamline workflows and allocate resources efficiently ultimately boosting productivity and cutting down on expenses.

Additionally MES systems are vital for ensuring adherence to standards and industry specific demands. Given the increasing regulations concerning safety, emissions and quality control automotive companies must comply with a range of guidelines to uphold their reputation in the market and maintain consumer confidence. MES systems offer tools for monitoring and documenting compliance throughout every phase of production thus reducing the risk of penalties, for non product recalls.

Plastic Industry

In the heart of the plastics industry MES systems act as platforms that bring together and coordinate different aspects of production from managing materials to overseeing quality control and more. In a field known for its range of products, fast production cycles and growing environmental concerns these systems offer a structure to streamline operations and promote ongoing enhancements.

MES systems play a role, in upholding standards and specific industry guidelines. With increasing worries about sustainability, product safety and recycling efforts plastic manufacturers encounter regulations and criteria to adhere to. These systems equip them with the tools to monitor and record compliance throughout the manufacturing process stages mitigating the risk of penalties due to non compliance while ensuring alignment, with sustainability objectives.

Food and Beverage Production

The food and beverage sector relies on MES to navigate the stringent maze of health and safety regulations, manage complex recipes, and maintain traceability of products reaching the consumer. It’s instrumental in achieving product consistency, minimizing waste, and bolstering production efficiency—key factors in an industry where profit margins are slim and consumer satisfaction is paramount.

Electronics and Technology

For the electronics and tech industry, characterized by swift innovation and complex manufacturing processes, MES minimizes the time it takes to bring new products to market. It guarantees precision, quality, and efficiency in production processes, vital for staying competitive in a market where technological advancements rapidly evolve.

Consumer Products

In the fast-moving consumer goods (FMCG) industry, MES enables organizations to handle diverse product portfolios and swiftly adapt to changing consumer trends. Real-time insights into production and inventory facilitate quick market responses, efficient handling of seasonal demands, and punctual product deliveries, ensuring consumer needs are met with precision.

Pharmaceuticals and Medical Devices

MES is crucial in the pharmaceuticals and medical devices sector for maintaining compliance with rigorous regulatory standards and ensuring product traceability. It adeptly manages complicated formulas, secures batch consistency, and meticulously records every manufacturing phase, ensuring products are safe for end-users and comply with global standards.

The Transformative Benefits of MES

Improving Visibility and Management

A advantage of using an MES lies in its capability to offer an overview of the manufacturing process. By gathering, up to the minute data from the production floor this system presents a picture of production tasks, resource usage and material movement. This increased transparency empowers manufacturers to base their decisions on data, pinpoint bottlenecks and tackle issues before they escalate.

Coordinating Production Activities

An MES solution streamlines the coordination of production activities by sharing information across teams and ensuring that resources flow smoothly through the production cycle. This level of synchronization and communication helps reduce downtime minimize errors and enhance the efficiency of the manufacturing workflow.

Tracing Product Details

Establishing a product traceability system is crucial for industries with regulations, like food and beverage medical devices and aerospace. MES software stands out in this area by allowing manufacturers to track product specifications and orders trace component origins and adhere to industry standards.

Enhancing Operational Efficiency

Through the collection and analysis of real time performance data an MES solution empowers manufacturers to make choices and optimize their production operations. By utilizing performance indicators (KPIs) and sophisticated analytics manufacturing companies can pinpoint areas that need enhancement boost production output and strive for improvement.

Top 7 Benefits of MES

Manufacturing Execution Systems (MES) are pivotal in modern manufacturing, offering a plethora of benefits by leveraging extensive data analytics to provide real-time insights. These insights are key to enhancing production efficiency and optimizing cost management. The core advantages of implementing an MES in manufacturing operations include:

1-Streamlining Operations: MES helps in identifying and eliminating activities that do not add value to the manufacturing process, ensuring that resources are focused on productive tasks.

2-Enhanced Quality Control: With MES, quality control data is communicated instantaneously, allowing for immediate action to halt production if defects are detected. This rapid response mechanism significantly minimizes waste, scrap, and the need for re-work, ensuring products meet quality standards consistently.

3-Faster Issue Resolution: MES enables quicker trace analysis and root cause diagnosis, facilitating swift resolution of production issues. This rapid response capability enhances operational efficiency and reduces downtime.

4-Inventory Optimization: By updating inventory records in real-time with information on new production, scrap, and non-conforming materials, MES ensures accurate inventory levels. This precision aids purchasing, shipping, and scheduling departments in making informed decisions, thereby reducing excess inventory and associated costs.

The Difference Between MES & MOS

5-Continuous Product and Process Improvement: MES provides a foundation for ongoing improvement in product quality and design through detailed analysis and feedback on manufacturing processes.

6-Data-Driven Decision Making: The system supports fact-based decisions for both operational and strategic planning, ensuring that every decision is backed by accurate, real-time data.

7-Comprehensive Process Control: Offering complete oversight over the manufacturing process, MES empowers manufacturers with the ability to monitor, control, and optimize every aspect of production, from raw material usage to final product delivery.

Incorporating a MES into the manufacturing infrastructure transforms how operations are managed, offering a competitive edge through improved efficiency, quality, and decision-making capabilities. The system’s ability to provide a holistic view of the manufacturing process, combined with its analytical tools, makes it an indispensable asset for any manufacturing entity aiming for excellence in the digital age.

The Future of Manufacturing Execution Systems

As the manufacturing industry evolves Manufacturing Execution System systems will play a role, in driving innovation, flexibility and competitiveness. Companies that embrace the potential of MES will be well equipped to tackle challenges, such as supply chain disruptions and evolving customer needs.

Adopting Predictive Maintenance and Analytics

By incorporating analytics and predictive maintenance features into MES systems manufacturers can predict equipment failures plan maintenance schedules and optimize asset utilization. This predictive approach can minimize downtime cut maintenance expenses. Enhance equipment efficiency.

Utilizing Augmented Reality and Digital Twins

The integration of MES with cutting edge technologies like augmented reality (AR) and digital twins will transform how manufacturers engage with their production processes. AR driven MES solutions offer real time guidance, remote support and improved visualization capabilities. Digital twins enable scenario based planning and simulation to streamline production workflows.

Encouraging Collaborative Manufacturing Networks

In the age of Industry 4.0 MES systems will be instrumental, in fostering manufacturing networks.By facilitating sharing of information and coordination throughout the supply chain MES will give manufacturers the ability to better meet market needs make use of resources and promote ongoing enhancements. Click the link to read the Gartner Magic Quadrant for Manufacturing Execution Systems report.

Leading Vendors in the MES Landscape

The Manufacturing Execution System market is teeming with vendors offering a range of solutions designed to cater to the diverse needs of manufacturing operations, both on-premises and in the cloud. Among these, ProManage stands out as a distinguished provider with its innovative ProManage Cloud Next-Gen MES platform.

This system is engineered to provide manufacturers with enhanced visibility, control, and efficiency across their entire operations. By leveraging ProManage, businesses can significantly boost their productivity and quality, sharpen their competitive edge, diminish operational expenses, and lessen their environmental footprint. The platform facilitates rapid, data-informed decision-making, thereby accelerating the journey towards digital transformation. ProManage is committed to delivering solutions that are not only advanced but also user-friendly, ensuring that manufacturers can easily adopt and benefit from the latest in Manufacturing Execution System technology. For those looking to modernize their manufacturing processes, ProManage offers a comprehensive suite of features designed to meet and exceed industry demands. Please contact us to discuss ProManage Cloud Next-Gen MES platform’s core features in detail and how it can help you.

Let us help you embark on the journey of digital transformation.