In today’s fast-paced manufacturing landscape, efficiency on the shop floor is crucial for staying competitive. One key tool that has emerged to enhance this efficiency is the Manufacturing Execution System (MES). MES serves as a bridge between the shop floor and higher-level management systems by providing real-time data and insights that enable better decision-making and streamlined operations. In this discussion, we will explore how a MES software plays a pivotal role in enhancing efficiency on the shop floor.

How MES (Manufacturing Execution System) Enhances Efficiency?

A Manufacturing Execution System (MES) serves as the conductor on the shop floor, orchestrating various elements to create a harmonious symphony of efficiency. By integrating data, processes, and people, MES enhances efficiency in several key areas:

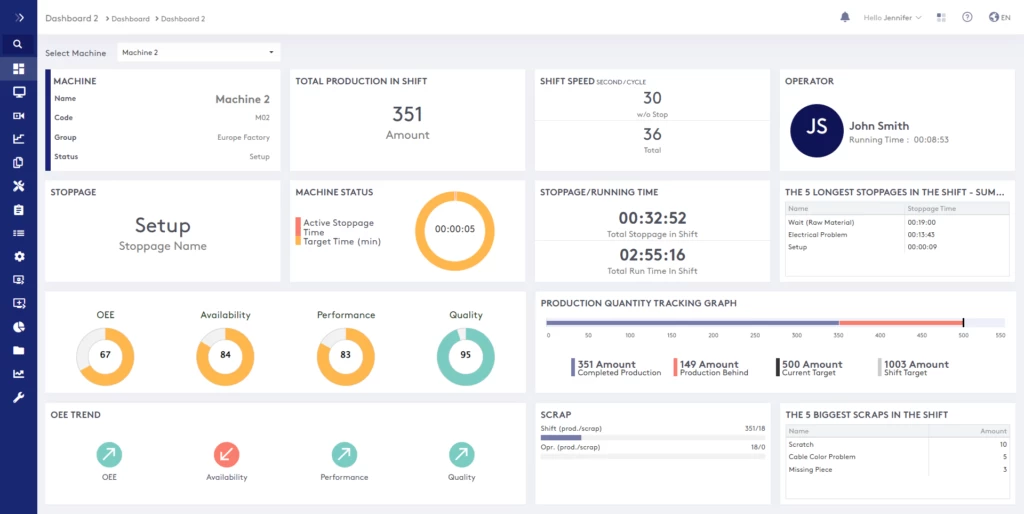

- Real-time Visibility and Data-driven Decisions: MES provides a real-time window into shop floor activities, tracking machine performance, resource allocation, and production progress. This visibility allows managers to quickly identify bottlenecks, respond to issues promptly, and make informed decisions to optimize operations. The ability to react swiftly to changing conditions and data-driven insights leads to a more agile and efficient production process.

- Streamlined Operations and Resource Management: MES orchestrates the flow of materials, labor, and equipment, ensuring that resources are utilized effectively. It assigns tasks to personnel based on their skills and availability, optimizing production scheduling to minimize downtime and ensure just-in-time delivery of materials. This coordination reduces waste, enhances productivity, and keeps operations running smoothly.

- Improved Quality Control and Reduced Defects: By integrating with quality control systems, MES enables real-time product quality monitoring, allowing for the early detection of defects. This prevents defective products from progressing further down the production line, reducing rework and scrap. Additionally, MES facilitates data collection for root cause analysis, helping to identify and address the underlying causes of quality issues, thereby improving overall product quality.

- Enhanced Communication and Collaboration: MES acts as a central hub for communication, fostering collaboration between different departments. Production personnel can easily access work instructions and updates, while maintenance teams can be alerted to potential equipment problems before they cause downtime. This transparency and information sharing lead to better coordination, faster problem-solving, and a more cohesive working environment.

- Increased Productivity and On-time Delivery: By eliminating inefficiencies, improving resource allocation, and reducing downtime, MES paves the way for increased productivity. Utilizing real-time production tracking leads to better schedule adherence, resulting in timely delivery and heightened customer satisfaction. The ability to meet delivery commitments consistently not only strengthens customer relationships but also positions the company as a reliable partner in the supply chain.

It goes without saying that MES plays a critical role in enhancing efficiency on the shop floor by providing real-time visibility, streamlining operations, improving quality control, enhancing communication, and increasing productivity. With the arrival of Industry 4.0 and smart factories, MES will play an increasingly important role in achieving operational excellence and gaining a competitive edge in manufacturing. By leveraging the capabilities of MES, manufacturers can optimize their processes, reduce costs, and ultimately drive business success in today’s dynamic and challenging market environment.

Want a Reliable MES Solution?

ProManage is your go-to solution for transforming traditional manufacturing into a more agile, efficient, and responsive ecosystem. Leveraging the power of IoT, ProManage Cloud ushers in a new era of Next-Gen MES, offering end-to-end functionality and technology with a simplified, no-code, modular, and leveled approach.

As a reliable and highly effective MES system, ProManage Cloud is not just a tool; it’s a strategic partner that streamlines daily operations for manufacturers striving for excellence in their industries. Whether your goal is to achieve Tier 1 status, lead the competition, attain sustainability, or master cost management, ProManage Cloud propels your manufacturing operations forward with transparency, simplicity, data-driven insights, lean practices, and modernity.

Our unique step-by-step approach breaks down barriers and creates an opportunity to start small and scale at your own pace. This smooth, scalable method ensures a seamless transition to smart manufacturing. You can begin with simple production monitoring and gradually expand to one of the most comprehensive Manufacturing Operations Management (MOM) functionalities. Each usage level and function set is designed for your success, backed by our 25 years of experience in Lean Management and next-generation MES. With ProManage, you are assured of a journey towards operational excellence and a competitive edge in your industry.

[formsite host=”fs26″ key=”m_OmK8apOTD1rsQA7j37rujXAIk-siNwK5oMHUOxJy8″ width=”100%”]