Today, we live in an interconnected world where global supply chains have become the backbone of manufacturing industries. That said, the past few years have been difficult, with unprecedented disruptions ranging from the COVID-19 pandemic to geopolitical tensions, labor challenges, and raw material shortages. These complications have forced manufacturers to rethink and adapt their strategies to ensure consistent growth and capability to meet the demands.

Here, we will explore how manufacturers are tackling global supply chain challenges through key strategies and innovative solutions, with a special focus on the transformative role of manufacturing execution systems (MES) like ProManage Cloud, a Next-Generation MES platform that plays a pivotal role in revolutionizing manufacturing industries with its cutting-edge, IoT-based smart systems.

Understanding The Role of Digital Transformation in Supply Chain Management

It has now become clear to many manufacturing industries that digital technologies are here to stay – that they are at the heart of modern supply chain optimization. We’re talking about AI, advanced analytics, and IoT, which are helping manufacturers gain deeper insights, automate processes, and make result-oriented data-driven decisions.

Take predictive analytics for demand forecasting as an example. This AI-powered tool does a commendable job of analyzing historical data, market trends, and external factors to predict demand more accurately. As a result, it enables better planning for production, procurement, and inventory management.

Then, there is IoT for real-time tracking. The IoT sensors and devices provide real-time visibility into inventory levels, transit conditions, and equipment performance. All this collected data then helps manufacturers respond swiftly to potential disruptions.

Embracing Next-Gen MES Solutions

There’s no denying that MES solutions have now emerged as essential tools for navigating supply chain challenges. This makes sense since they bridge the gap between enterprise systems and shop-floor operations to enhance efficiency, traceability, and quality management.

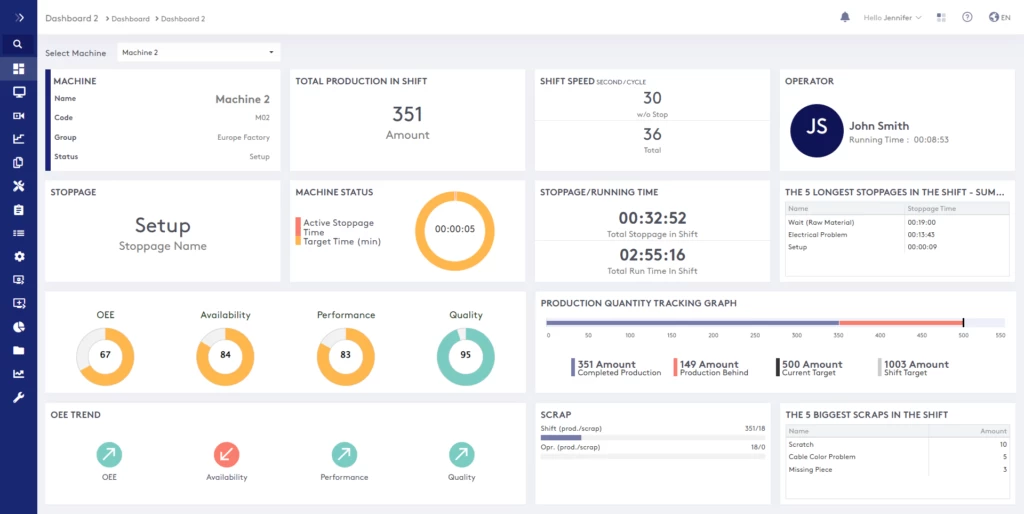

Take the example of ProManage Cloud’s Next-Generation MES solution, which redefines the future of manufacturing. It refines the future by providing end-to-end functionality and leveraging IoT to simplify manufacturing operations with a no-code, modular, and leveled approach.

In other words, it enables manufacturers to deploy and customize MES solutions without extensive coding expertise. Moreover, the ProManage Cloud Next-Gen MES solution collects and analyzes real-time data from machines, operators, and processes, which then helps with seamless monitoring, predictive maintenance, and optimization of production workflows.

Last but not least, it has a user-friendly interface and advanced analytics, which help manufacturers reduce downtime and waste, enhance productivity and quality, and make informed decisions based on real-time data.

Moving To Sustainability in Supply Chains

It is becoming evident that Sustainability is no longer a choice but a necessity for manufacturers. Consumers, governments, and stakeholders demand environmentally friendly practices, and sustainable supply chains are key to this shift.

Also, there is a focus on green manufacturing practices, which involve adopting energy-efficient processes, reducing waste, and sourcing materials to create a more sustainable manufacturing ecosystem.

Collaboration and Partnerships for Supply Chain Optimization

We now understand that collaboration is extremely critical to overcoming supply chain challenges. Manufacturers are forging closer partnerships with suppliers, logistics providers, and technology firms to create more resilient ecosystems.

That said, Partnering with MES providers like ProManage Cloud helps manufacturers integrate the latest innovations into their operations, enhancing efficiency and competitiveness. After all, sharing real-time data with MES across the supply chain can allow your stakeholders to align their operations, improve forecasting, and avoid disruptions.

Looking Ahead: The Future of Global Supply Chains

The future of global supply chains will demand a relentless focus on resilience, agility, and innovation as manufacturers navigate an increasingly volatile landscape. To stay competitive, businesses must proactively adapt their strategies and leverage cutting-edge technologies. Next-generation solutions like ProManage Cloud are set to redefine manufacturing operations, empowering companies to:

- Build more resilient and agile supply chains by enhancing visibility, optimizing workflows, and reducing vulnerabilities.

- Meet evolving consumer demands with unmatched efficiency and precision, ensuring timely delivery of high-quality products.

- Drive sustainable growth through smart, data-driven practices that optimize resource use, reduce waste, and align with global sustainability goals.

Implementing these advancements will allow manufacturers to transform challenges into opportunities and secure their position as industry leaders in the growth age.

Cloud-Based Manufacturing: The Role of OPC UA and MES Integration

The Key Takeaway

Global supply chain challenges are testing manufacturers like never before, but they also present opportunities for growth and transformation. By adopting robust strategies, leveraging advanced technologies like ProManage Cloud, and fostering collaboration, manufacturers can overcome these hurdles and achieve lasting success.

It is high time you empowered your manufacturing excellence today with ProManage Cloud’s Next-Generation MES/MOM system. With its IoT-based, no-code, modular approach, ProManage is your gateway to a smarter, more resilient, and more efficient future. Contact us today to discuss its immense potential in detail.