Artificial Intelligence presents a transformative solution to the challenges faced by Manufacturing Execution Systems (MES). By incorporating AI, MES software providers can elevate their offerings from merely presenting data to providing valuable, actionable information to their users. For Instance, AI-driven fine planning, equips decision-makers with insightful recommendations, enhancing their ability to make informed and effective decisions in the manufacturing process. In fact, you’d be surprised to know that decision-making can be improved up to 40% by simply using AI. Let’s explore the transformative potential of integrating MES and AI.

Maximize MES Software’s Potential With Artificial Intelligence

Traditional MES (Manufacturing Execution System) software offers a strong foundation for production management, but AI-powered production planning can elevate MES providers to a whole new level. Here’s how:

Automated Decision-Making

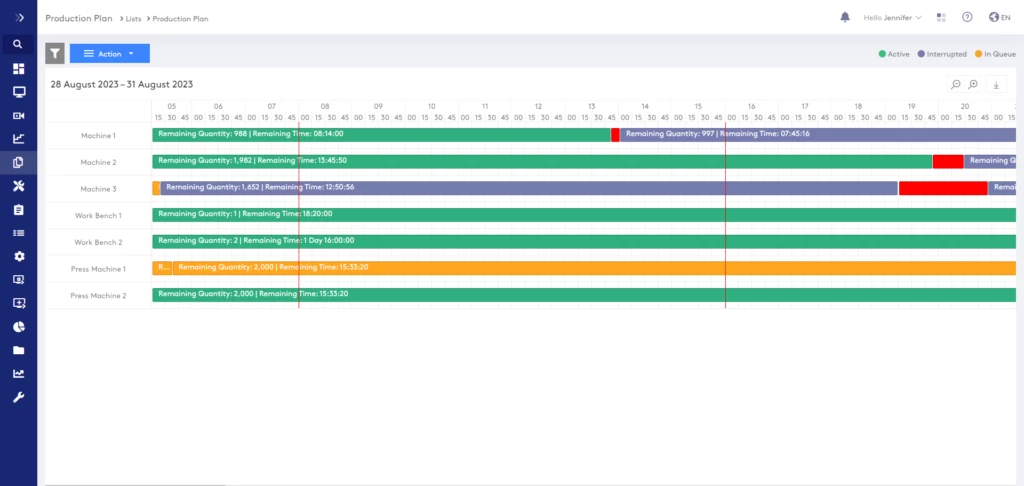

AI is revolutionizing MES software by enabling the analysis of massive datasets that include historical data, real-time production information, and external market trends. This capability empowers MES providers to develop software that not only suggests optimized production schedules but also identifies potential risks and recommends mitigation strategies.

By leveraging AI, MES can provide manufacturers with actionable insights, enabling them to make data-driven decisions that enhance operational efficiency, minimize downtime, and adapt to changing market dynamics. This level of automation and intelligence in decision-making allows manufacturers to stay ahead of the competition by optimizing their production processes and responding proactively to potential challenges.

Enhanced Efficiency and Productivity

One cannot deny that AI’s ability to analyze vast amounts of production data in real-time enables it to identify bottlenecks and inefficiencies with remarkable precision. Consequently, this leads to optimized scheduling, better resource allocation, and targeted process adjustments, resulting in smoother operations and increased output.

A study by McKinsey estimates that AI-driven process optimization has the potential to increase manufacturing efficiency by up to 20%. This significant improvement can be attributed to AI’s capacity to provide deep insights and recommendations that enable manufacturers to fine-tune their production lines, reduce waste, and maximize the utilization of available resources, ultimately leading to higher productivity and competitiveness in the market.

Real-Time Adaptability

Production environments are inherently dynamic, necessitating a system that can swiftly adapt to changes. AI excels in this aspect by continuously monitoring data streams from the manufacturing process. It can detect disruptions such as equipment failures or supply chain issues in real-time and prompt the MES to automatically adjust production schedules accordingly.

This capability ensures greater responsiveness to unforeseen events, minimizing downtime and maintaining smooth operations. By enabling a more agile and flexible manufacturing environment, AI contributes to enhanced productivity and ensures that production processes remain uninterrupted, even in the face of unexpected challenges.

Enhanced Predictive Maintenance

Predictive maintenance is a game-changer in the manufacturing industry, thanks to the integration of AI with sensor technology. AI algorithms can analyze sensor data collected from equipment, such as vibration, temperature, and noise levels, to predict potential failures before they occur. This proactive approach allows maintenance teams to address issues before they lead to breakdowns, preventing unplanned downtime and ensuring that machines are operating at peak performance.

Furthermore, predictive maintenance can extend the lifespan of equipment by identifying and rectifying problems early, reducing the need for costly replacements. It also optimizes maintenance schedules, ensuring that resources are used efficiently and maintenance is performed only when necessary. By minimizing disruptions and maintaining optimal equipment performance, predictive maintenance contributes to increased productivity and reduced cost, making it a vital component of modern manufacturing operations.

Improved Quality Control

Improved quality control is a significant advantage of integrating Artificial Intelligence (AI) with MES. AI can analyze production data in real-time, identifying quality issues early in the production process. By detecting anomalies or deviations from the standard, AI enables manufacturers to take swift corrective actions, reducing the number of defective products and enhancing overall product quality.

Furthermore, AI integration with MES can help establish predictive quality models that anticipate potential quality issues based on historical data and current production trends. This proactive approach allows manufacturers to address quality concerns before they escalate, minimizing waste and rework. By ensuring consistent product quality, AI-driven MES contributes to customer satisfaction, brand reputation, and compliance with industry standards, making it a valuable tool for quality control in modern manufacturing environments.

Demand Forecasting

Demand forecasting is significantly enhanced by the integration of AI into the manufacturing process. AI algorithms can sift through vast amounts of historical sales data and market trends to accurately predict future product demand . This predictive capability enables manufacturers to plan their production schedules more effectively, ensuring they can meet customer demand without overproducing.

By aligning production with anticipated demand, manufacturers can optimize their inventory levels, reducing the risk of stockouts or excess inventory. This not only leads to cost savings but also enhances customer satisfaction by ensuring product availability. Additionally, AI-driven demand forecasting can help manufacturers respond more swiftly to market changes, providing a competitive edge in rapidly evolving industries. Overall, integrating AI into demand forecasting empowers manufacturers to operate more efficiently and adaptively in today’s dynamic market landscape.

Is AI-MES Integration The Future of Manufacturing?

Integrating AI-powered production planning into MES software allows providers to deliver a more sophisticated and intelligent solution to manufacturers. This integration can serve as a key differentiator in a highly competitive market.

Envision an MES that not only monitors production data but also leverages AI to forecast equipment maintenance requirements, streamline inventory management, and recommend proactive measures to reduce downtime. Such advanced functionality would revolutionize the manufacturing industry and provide MES providers with a distinct advantage in the marketplace.

Get Your AI-Powered MES Software Today

Step up your manufacturing game with ProManage’s AI-powered MES software! Imagine having a clear view of everything happening in your operations, all thanks to the magic of IoT. Our software turns complex production data into easy-to-understand information in real-time, boosting your productivity, quality, and competitiveness while keeping costs and environmental impact low.

Harness the power of ProManage to make rapid, informed decisions, anticipate market shifts, and elevate your overall performance. Experience our user-friendly platform powered by cutting-edge technologies including IoT, edge computing, cloud computing, AI, and computer vision. With these tools assisting, you can effortlessly adjust to any changes, new workflows, or advancements in your plant.And don’t worry about the journey to becoming a Smart Factory – we’ve got you covered with a step-by-step approach that matches your pace. Start small and expand to a top-notch Next-Gen MES as you’re ready. Let’s connect and discuss the potential in detail.