Did you know the CNC market is on an impressive trajectory, forecasted to expand from $86.83 billion in 2022 to $140.7 billion by 2029? This exponential surge represents a remarkable 61% growth within a few upcoming years. It makes sense since the expansion is driven by the evolving economic landscape and a growing trend towards personalized products, indicating a bright future for CNC technology.

CNC machines, the backbone of modern manufacturing, are celebrated for their precision and efficiency in producing parts. These machines play a pivotal role in shaping the future of production. Now, let’s take a closer look at an essential aspect of modern manufacturing: CNC machine data collection.

What is CNC Machine Data Collection?

Computer Numerically Controlled (CNC) Machine Data Collection is about tapping into the rich vein of information that CNC machines generate during operation. It involves capturing, analyzing, and leveraging data to refine and enhance manufacturing processes. This data offers insights into machine performance, enabling manufacturers to pinpoint inefficiencies and fine-tune their operations. By understanding patterns in machine use, production rates, and potential errors, companies can improve accuracy, minimize downtime, and boost overall productivity.

Moreover, this data collection is instrumental in predictive maintenance strategies, allowing for the anticipation and mitigation of potential machine failures before they disrupt production. In essence, CNC Machine Data Collection is a strategic approach to harnessing the power of information to elevate manufacturing efficiency and extend the life of machinery, leading to more sustainable and cost-effective production processes.

The Imperative Nature of Data Collection

The significance of data collection in CNC machining cannot be overstated, given its capacity to transform raw operational inputs into actionable intelligence. This process involves capturing a vast array of information that CNC machines generate during their operation, which can be categorized into several key areas:

- Machine Status: This dimension offers insights into the operational state of the CNC machine at any given time, indicating whether it is actively machining, idle, or in a maintenance phase. Understanding machine status in real-time allows for more effective scheduling and utilization of resources, ensuring that machinery is not lying idle when it could be productive, or conversely, that maintenance is performed to prevent unexpected breakdowns.

- Process Parameters: These include critical operational data such as spindle speed, feed rate, cutting tool details, and other specific parameters that govern the machining process. By monitoring these parameters, manufacturers can ensure that the machining process is optimized for speed, efficiency, and material usage, leading to cost savings and improved throughput.

- Part Metrics: This aspect focuses on the quality and accuracy of the parts being produced, including measurements of dimensional accuracy, surface finish, and any deviations from the predetermined specifications. Close monitoring of part metrics is essential for maintaining high standards of product quality and minimizing waste due to defects or rework.

- Power Consumption: Tracking the energy usage of CNC machines provides valuable insights into the overall efficiency of the manufacturing process. It can identify machines that are consuming excessive energy, perhaps due to inefficient operation or the need for maintenance, thus offering opportunities to reduce costs and the environmental impact of manufacturing activities.

The strategic collection and nuanced analysis of this diverse data yield several significant benefits:

- Optimizing Production Flow: By identifying and addressing production bottlenecks, operations can be streamlined, reducing cycle times and increasing output. Data-driven adjustments to process parameters can lead to more efficient use of machinery and materials.

- Maintaining Product Quality: Real-time data monitoring enables the early detection of deviations from quality standards, allowing for immediate corrective actions to be taken. This ensures that the final product consistently meets or exceeds customer expectations, thereby enhancing brand reputation and customer satisfaction.

- Implementing Predictive Maintenance: Predictive analytics can be applied to the data collected from CNC machines to forecast potential equipment failures before they occur. This proactive approach to maintenance can significantly reduce downtime, associated costs, and the risk of unfulfilled orders due to machine failure.

- Enhancing Operational Decision-Making: Armed with comprehensive and accurate data, managers and decision-makers can make more informed choices regarding production scheduling, resource allocation, and process improvements. This leads to a more agile, responsive, and efficient manufacturing operation, capable of adapting to changing market demands and challenges.

ProManage Can Help Transform Your Underperforming Traditional Manufacturing

In the modern manufacturing landscape, the transition from traditional practices to smart manufacturing is pivotal for staying competitive. This transformation begins with the integration of web-enabled, shop-wide machine monitoring systems. ProManage stands at the forefront of this revolution, offering a CNC machine monitoring solution that is not only precise and real-time but also incredibly user-friendly and versatile, capable of integrating with any machine type.

Our system is designed to be the linchpin for manufacturers seeking to leverage the full potential of their production data. With ProManage, the complex becomes simple: our software’s seamless integration and ease of use mean that bringing smart manufacturing capabilities to the factory floor is no longer a daunting task. It is a powerful tool that translates data into actionable insights, allowing for the optimization of machine utilization across the board.

The success of ProManage Cloud is attributed to its support, for a variety of communication protocols. This ensures compatibility across Programmable Logic Controllers (PLCs) and machine control systems. By accommodating communication protocols like OPC UA, OPC DA, Modbus TCP/IP, MQTT, Fanuc Focas Ethernet, MTConnect, EuroMap63/77 and ProfiNET (Siemens) it offers a solution for data collection regardless of the machine type.

ProManage Cloud facilitates communication with used FANUC controllers found in CNC machines without requiring any additional software. Furthermore it enables interaction, with controllers through MT Connect compatibility. Through research and development initiatives ProManage Clouds communication infrastructure is constantly advancing by incorporating protocols.

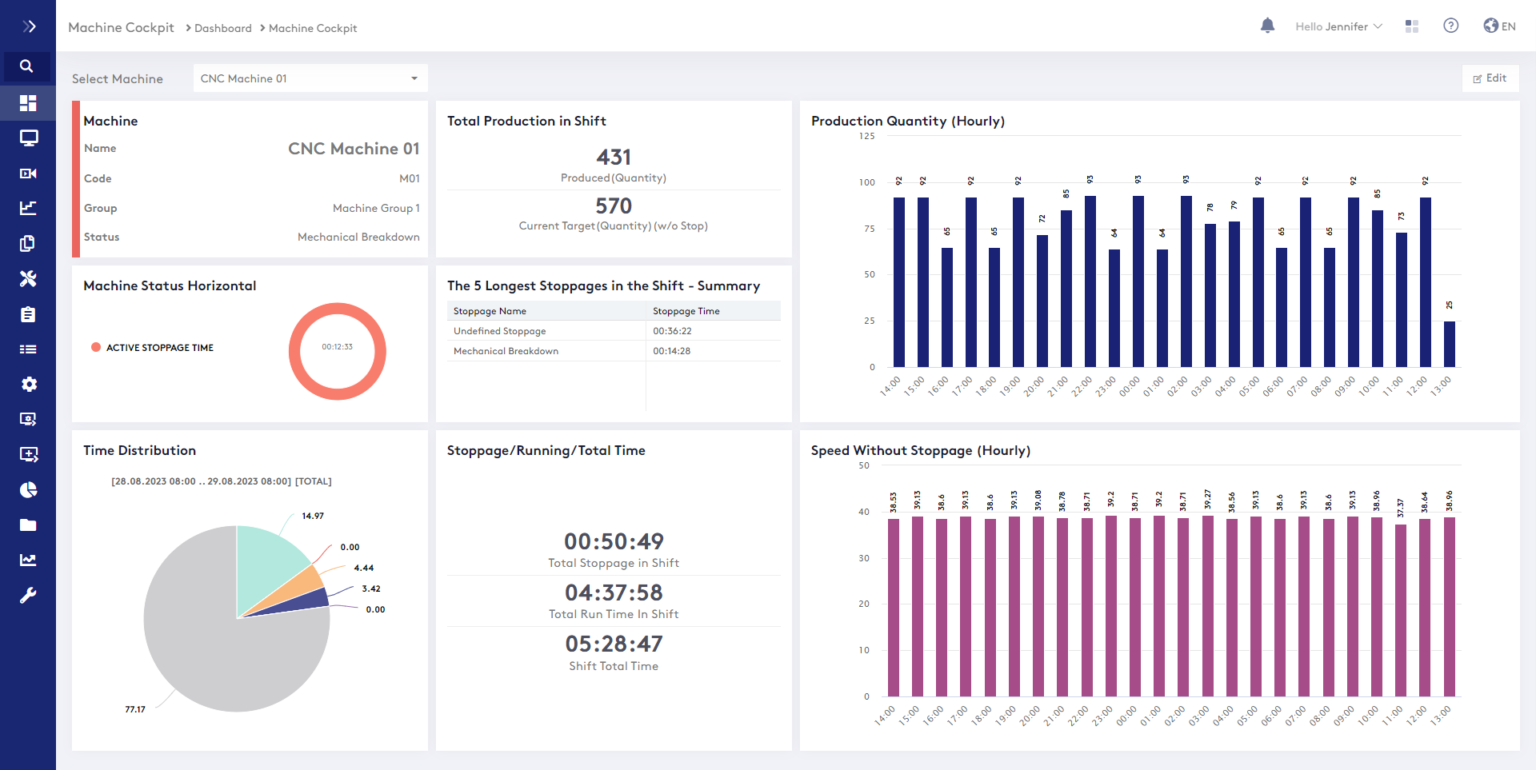

ProManage’s fully automated CNC machine monitoring systems and Overall Equipment Effectiveness (OEE) software elevate the manufacturing process by providing vivid visualizations of manufacturing production data in real-time. This includes instant notifications of critical issues and in-depth historical analytics. Such comprehensive visibility empowers factory workers and decision-makers alike to make informed, confident decisions swiftly, enhancing productivity and efficiency.

The strength of our machine monitoring software lies in its ability to provide immediate insights into OEE, pinpoint production bottlenecks with precision, and quantitatively assess the impact of process improvements. This real-time tracking and analysis enable a dynamic response to operational challenges, facilitating continuous improvement and lean manufacturing practices.

Moreover, ProManage is tailored for manufacturers who aspire to bolster shop floor communication, skyrocket OEE, and adopt a culture of data-driven decision-making. The integration of our software into your manufacturing operations not only bridges the gap between traditional and smart manufacturing but also transforms your factory floor into a hub of efficiency and innovation.

In essence, ProManage equips manufacturers with the tools necessary to not just compete but excel in an increasingly digital and data-driven industry. By embracing our machine monitoring solutions, manufacturers can unlock the full potential of their operations, resulting in enhanced productivity, reduced waste, and ultimately, a stronger bottom line. Transforming underperforming traditional manufacturing into a modern, efficient, and data-empowered enterprise becomes not just an aspiration but a reality with ProManage by your side.