Artificial Intelligence presents a transformative solution to the challenges faced by Manufacturing Execution Systems (MES). By incorporating AI, MES software providers can elevate their offerings from merely presenting data to providing valuable, actionable information to their users. For Instance, AI-driven fine planning, equips decision-makers with insightful recommendations, enhancing their ability…

In today’s fast-paced manufacturing landscape, efficiency on the shop floor is crucial for staying competitive. One key tool that has emerged to enhance this efficiency is the Manufacturing Execution System (MES). MES serves as a bridge between the shop floor and higher-level management systems by providing real-time data and insights that…

The key for manufacturers looking to transform their production processes lies in applying agile manufacturing principles. A crucial step is integrating Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES). But why is this integration so important Because MES and ERP integration enables seamless communication between the shop floor and…

In the manufacturing industry, traditional Manufacturing Execution Systems (MES) are no longer sufficient to meet the demands of the constantly evolving landscape. Manufacturers face challenges, such as limited budgets, time constraints, and uncertainties in their path to digital transformation. This has given rise to the emergence of next-generation MES solutions…

We live in a fast-paced business world, where staying competitive means not only having a great product but also making sure it’s produced efficiently and to the highest quality. To achieve that, there’s a game-changing tool that savvy businesses are using to keep their production lines humming smoothly, minimize disruptions,…

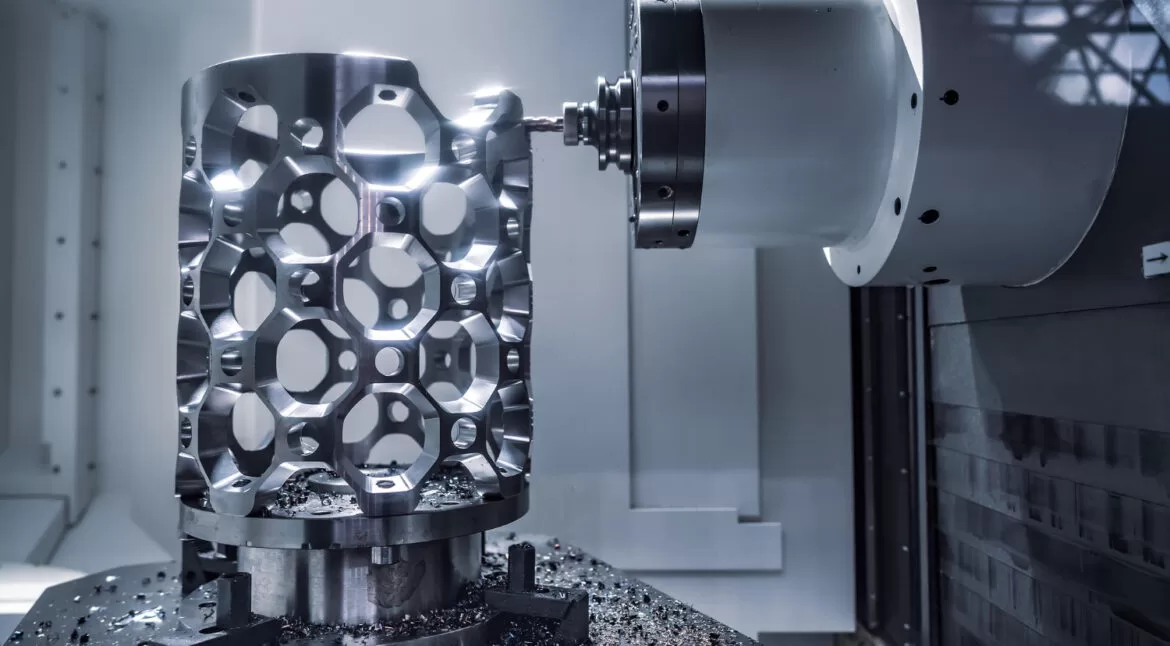

Did you know the CNC market is on an impressive trajectory, forecasted to expand from $86.83 billion in 2022 to $140.7 billion by 2029? This exponential surge represents a remarkable 61% growth within a few upcoming years. It makes sense since the expansion is driven by the evolving economic landscape…

Nowadays, manufacturers are under pressure from the competition, small orders, shortened delivery terms, supplier audits, employee shortages, economic difficulties, etc. Smart manufacturing is the answer to these difficulties. Some of the benefits of managing manufacturing operations digitally and automatically with the help of IoT based real-time smart systems are: •Factories…

In the globalizing economy, nearly all components, such as machines, raw materials and technology, that are used while manufacturing values..

In today's world, our processes are now more "automatic" due to the increased involvement of PLC..

All manufacturing companies have the same objectives on the path to success; 1. Increase the revenue..