We are in the age of speed.

The world is spinning much faster than it did just a few years ago, even yesterday...

Trends, competition conditions, costs, and profits differ very quickly. Not being able to keep up with the pace of the new economy means not falling behind but staying out of the race. Besides, it’s not enough to be fast. At the same time, you must be smart, efficient, and error-free. You should increase your production efficiency and maximize your management skills. Some call it operational excellence.

However, we do not believe in perfection. Because excellent companies do not believe in perfection but in continuous improvement. Production, technology, logistics, and people… There is always something to improve for the big minds who run big companies, even in the most perfect operation.

The “perfect” is temporary for companies changing the planet; “development” is permanent. It is not a preference; it is an automatic form of management.

So do we…

Harry Oliver,

CEO of Steeler Industrial

ProManage is a technology company with an interdisciplinary approach working on IIoT, AR (Augmented Reality), and AI (Artificial Intelligence) technology areas for Manufacturing Operations Management.

ProManage supports manufacturers to be more productive, agile, and cost-efficient by using cutting-edge digital tools in Manufacturing Operations Management (MOM) for more than 25 years.

ProManage helps the manufacturers’ Industry 4.0 digitalization journey to transform their plant into a smart factory and provides advanced analytics for manufacturing, predictive maintenance management, predictive quality management, and predictive decision.

ProManage has had 50,000+ of operating manufacturing points at 500+ prominent customers for 25 years.

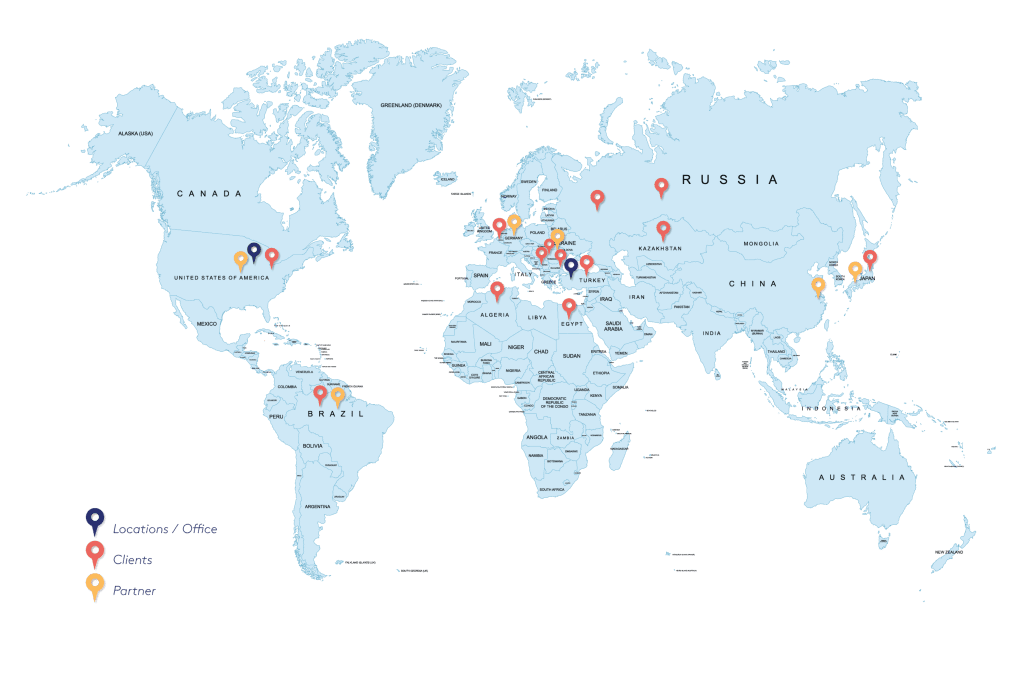

Products and services are offered on 5 continents.

Since 2017, international expansion has been headquartered in U.S. (Chicago, MxD, UILABS)

R&D Center serving globally with Smart Factory & Smart Manufacturing concepts within Industry 4.0.

120+ highly qualified & agile engineer resources profile.

Serves for discrete manufacturing Industry Automotive, Metal Processing, Home Appliances, Plastics, Food, FMCG, etc

Our Mission

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus. Aenean ut velit hendrerit, interdum mi id, fringilla erat.

Our vision

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus. Aenean ut velit hendrerit, interdum mi id, fringilla erat.

Our commitment

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus. Aenean ut velit hendrerit, interdum mi id, fringilla erat.

Ready to Bring Bigger, Better, Faster And Stronger

Projects Than Ever Before!!

25 year experience

With over 25 years of experience in the field of industrial manufacturing, we guarantee the best quality and products.

professional team

With a professional team of steelers, we are all experienced and highly skilled in manufacturing. Lorem Ipsum is simply dummy.

Safety is top priority

For us, occupational safety is a top priority, with modern machinery and safety facilities. so it’s well worth the investment in safety.

large scale

With 30 factories around the world, we are the leading industrial company for you. Free is a firm believer in working.

Looking for a reliable &

stable partner?

We seek for cooperation in various areas in order to achieve the purpose of diversifying and expanding our company’s operating fields. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer finibus varius sem, in aliquam magna sollicitudin a. Ut et dui vitae dolor scelerisque pulvinar non vel risus.

Let's Grow With

Steeler

We are an integrated engineering company composed of a group of agile and experienced engineers skilled in different business areas. Ut purus est, maximus sit amet porttitor id, bibendum a ante. Suspendisse erat erat, maximus eget venenatis nec

Brands That Trust ProManage Cloud

What Our Clients are Saying

1 +

Customer Satisfaction

Leonard Kohen

Company Owner – IMAP

“In our digitalization journey, we gained the ability to monitor OEE and productivity with ProManage. As IMAP, we lifted our production capacity by at least 15% thanks to ProManage. We have gained 25% increase in production efficiency. With ProManage, we have developed a transparent production method by analyzing our data correctly. ”

Can Erdin

Company Chairman – LABSAN

“We have prevented wasting time by the qualified data provided by ProManage, which we decided to take our digital steps together. Through the ProManage system, where we can make production more transparent, we have followed production efficiently with interventions on-site and on-time, and we have put our company one step forward!”

Gani Harputoğlu

Process Development and IT Manager - Nitto Bento

“By starting our digital transformation with ProManage, we achieved significant gains in manpower, energy efficiency and machine performance. By expanding our service area, we increased OEE data from 40% to 60% and to 85% for critical machines.”

Murat Aybakan

President - AISIN Turkey

“While moving towards being proactive with ProManage, with the help of real time data that we had we able to see the areas where we can interfere. This situation affected profitability, production efficiency, cost and competitiveness positively and bring AISIN Turkey in competency that distinguishes it from other factories.”

Hakan Ünlü

Vice President of Turkey and Africa Operations - Maxion Wheels

"Our ability to analyze our operations has increased with the visibility of the data infrastructure provided by ProManage! In this way, we have separated from operations all over the world, our contry has become a center of attraction and our competitiveness has increased!"

Abdullah Böyet

General Manager Asistant – Akplas

"We have prevented wasting time by the qualified data provided by ProManage, which we decided to take our digital steps together. Through the ProManage system, where we can make production more transparent, we have followed production efficiently with interventions on-site and on-time, and we have put our company one step forward."

Sadi Gökeer

Production and Engineering Director – KIRPART

"We made our process management transparent in the digital transformation journey we started with ProManage. We have increased OEE and capacity by detecting machine downtimes. We became stronger in our field by improving quality, maintenance and production efficiency."

Mehmet Şeref Ercan

Deputy General Manager of Olgun Celik

We implemented a more systematic and effective production planning process with ProManage and increased our production efficiency, improved our capacity volume by detecting breakdowns, quality losses and waiting times in machines, and increased our profitability in production by increasing our communication with the field!