Manufacturing Execution Systems (MES) are essential in modern manufacturing, serving as the backbone of production operations by linking enterprise-level business systems with the plant floor. MES systems have evolved significantly, incorporating cutting-edge technologies to meet the complex demands of contemporary manufacturing. Here are five things you may not have known about MES, providing insights that could transform your manufacturing processes.

MES: Beyond Basic Tracking

While MES is often recognized for its tracking and documentation capabilities, it extends far beyond these basic functions. Modern MES systems are comprehensive solutions that provide real-time data analysis, production scheduling, quality management, and compliance tracking. These capabilities help manufacturers optimize their processes, reduce waste, and enhance product quality.

In addition to these functions, MES can also facilitate predictive maintenance. By analyzing data from various machines and sensors, MES can predict potential failures and schedule maintenance activities proactively. This predictive capability helps maintain continuous production, minimizes downtime, and extends the lifespan of equipment, ultimately reducing costs and improving efficiency.

Moreover, MES systems can integrate with various other enterprise systems, such as Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), and Supply Chain Management (SCM) systems. This integration ensures seamless information flow across the organization, enhancing coordination and efficiency. By providing a unified platform for managing manufacturing operations, MES can significantly streamline production processes and improve overall operational performance.

Real-Time Data for Enhanced Decision-Making

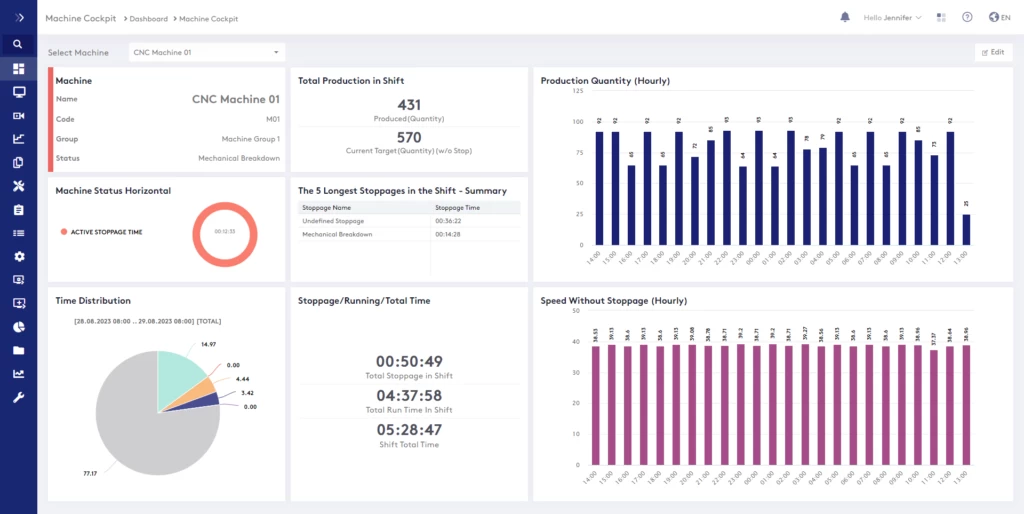

One of the most notable advantages of modern MES systems is their ability to provide real-time data from the production floor. This real-time data can be accessed and analyzed instantly, enabling immediate decision-making. With insights into production status, machine performance, and quality metrics, managers can quickly identify and address issues, minimizing downtime and maintaining optimal production efficiency.

Real-time data also enhances supply chain management by ensuring that materials and components are available when needed, reducing the risk of production delays. By synchronizing information between MES and supply chain systems, manufacturers can maintain an efficient and responsive manufacturing environment.

Additionally, real-time data can be used to improve product quality. MES systems can monitor quality parameters throughout the production process, identifying deviations from specifications and triggering corrective actions. This capability helps ensure that products meet quality standards, reducing the risk of defects and enhancing customer satisfaction.

Seamless Integration with Enterprise Systems

MES systems are designed to integrate seamlessly with other enterprise systems, such as ERP, SCM, and PLM. This integration ensures a cohesive flow of information across the organization, from order management to production and delivery. By providing a unified view of the entire manufacturing process, MES enhances collaboration between departments, streamlines operations, and ensures that all stakeholders have access to accurate and up-to-date information.

The integration capabilities of MES also extend to IoT (Internet of Things) devices, allowing for granular data collection and analysis. By connecting various sensors and devices on the production floor to the MES, manufacturers can gain deeper insights into their operations. This connectivity enables better monitoring of environmental conditions, equipment status, and production metrics, leading to more informed decision-making and optimized processes.

Furthermore, MES systems can integrate with advanced analytics and artificial intelligence (AI) tools to provide predictive insights and recommendations. By leveraging these advanced technologies, manufacturers can identify patterns and trends in their data, enabling proactive maintenance, process optimization, and continuous improvement initiatives.

Scalability and Flexibility for Growing Businesses

As businesses grow and evolve, their manufacturing processes and requirements change. An effective MES must be scalable and flexible to accommodate these changes. Traditional MES systems often require significant reconfiguration or even replacement as business needs evolve, leading to increased costs and downtime.

Modern MES systems address this challenge with modular and leveled approaches. These systems allow manufacturers to start with essential modules and gradually add more functionality as needed. This scalability ensures that the MES grows alongside the business, adapting to new processes, technologies, and market demands without disrupting ongoing operations.

The no-code or low-code approach of many modern MES solutions allows for easy modifications and customization without extensive programming knowledge. This feature is particularly beneficial for businesses with limited IT resources, as it reduces the dependency on external consultants and accelerates the implementation of new features or adjustments to existing processes.

Scalability also means that the MES can handle an increasing volume of data and transactions as the business expands. As production scales up, the system can efficiently manage the additional workload without compromising performance. This capability is crucial for maintaining high levels of productivity and ensuring that the system can support future growth.

Enhanced Compliance and Traceability

In today’s regulatory environment, compliance and traceability are more critical than ever. MES systems play a vital role in ensuring that manufacturing processes adhere to industry standards and regulations. They provide comprehensive documentation of every step in the production process, from raw material receipt to finished product shipment.

MES systems offer detailed traceability and compliance features, ensuring that all production activities are documented and easily accessible for audits and regulatory inspections. The systems support electronic signatures and automated compliance checks, reducing the risk of non-compliance and associated penalties.

Traceability is not only about compliance but also about building consumer trust. In industries such as food and pharmaceuticals, consumers demand transparency regarding the origins and handling of products. An MES with robust traceability features can provide detailed records of each product’s journey through the supply chain, enhancing transparency and customer confidence.

In the event of a recall, having an MES with comprehensive traceability can significantly reduce the time and effort required to identify affected batches and take corrective action. This capability minimizes the impact of recalls on the business and helps maintain customer trust.

Here’s Why Your Business Needs MES

Manufacturing Execution Systems have come a long way from their origins as basic tracking tools. Today’s MES systems offer a wide range of functionalities that drive efficiency, improve quality, and support growth in manufacturing operations. By providing real-time data, seamless integration, scalability, and enhanced compliance, modern MES systems are indispensable tools for manufacturers aiming to stay competitive in a rapidly evolving industry.

At the heart of modern manufacturing, MES systems provide the critical infrastructure needed to manage complex production processes effectively. By leveraging advanced technologies such as IoT, AI, and real-time analytics, MES systems can transform manufacturing operations, driving continuous improvement and innovation.

For businesses looking to optimize their manufacturing processes, investing in a modern MES system is a strategic move that can yield significant benefits. From improving operational efficiency to ensuring compliance and enhancing product quality, MES systems offer a comprehensive solution that addresses the diverse needs of today’s manufacturers.

If you’re interested in learning more about how MES can transform your manufacturing operations, contact us at ProManage Cloud. Our team of experts can provide detailed information and guidance on how our MES solutions can help you achieve your operational goals and stay ahead of the competition. For more information, visit our website or reach out to us directly. Let ProManage Cloud help you unlock the full potential of your manufacturing capabilities.

[formsite host=”fs26″ key=”m_OmK8apOTD1rsQA7j37rujXAIk-siNwK5oMHUOxJy8″ width=”100%”]